The Benefits of a Wrinkle Remover Roller

In this industry-centric blog, we are going to highlight about wrinkle remover roller with the hope that the vital information will help industry people as well as general readers in expanding their knowledge about the product. The product is widely known as a rubber roller in industry circles. Before we move forward, let’s understand the product in simple language. It will help readers to relate better to the product. Understanding the industrial product A rubber rollers is an important machine part. The product comprises an inner round shaft or tube covered by an outer layer of elastomer compounds. The inner shaft of the product is made of sturdy steel, aluminum, or other rigid material composites. Coming to its importance and applications, industrial wrinkle remover rollers or rolls are used in various applications, particularly the removal of wrinkles. It is a product that is tailored for applications that require a high degree of contact and holding friction. In addition, the product is ideal for material processing. Significant features of the product The manufacturing industry-centric roller is widely acclaimed in the industry circles for numerous salient features, enabling companies to meet their production-related goals. These include: Additionally, the product is also known for less maintenance and durability. As an owner of a manufacturing company or senior professional, you require a product that delivers optimized performance, at the same time durable in nature. A product should be worth investing in. Only buy the product from genuine and recognized rubber roller companies. Application Types of wrinkle remover roller There is no dearth of rubber roller companies in the market which are manufacturing industrial rollers in Ahmedabad, India. Depending on your industrial setup and requirement, you can choose the product. Some of the popularly used rollers in the market are: Specification Industrial product is available in various dimensions. According to your requirement, choose the product. Custom-made A few companies deliver custom-made specifications. In case, the standard dimensions don’t meet your requirements, you can collaborate with a leading rubber roller company that holds expertise in custom-made solutions. How does it happen? Leading companies have the competency and facility to deliver manufacture custom-made solutions. Engineers and technicians headed by a senior design engineer enter into a dialogue with the engineers of clients. Both the team brainstorms. Subsequently, based on the industrial requirement, a design is developed. Industries drawing benefits from the industrial product This product has been a remarkable invention for numerous industries. Here is a list of a few industries drawing multiple benefits from the Join hands with the industry leaders Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber rollers, metal rollers, bow rollers, air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver among others.

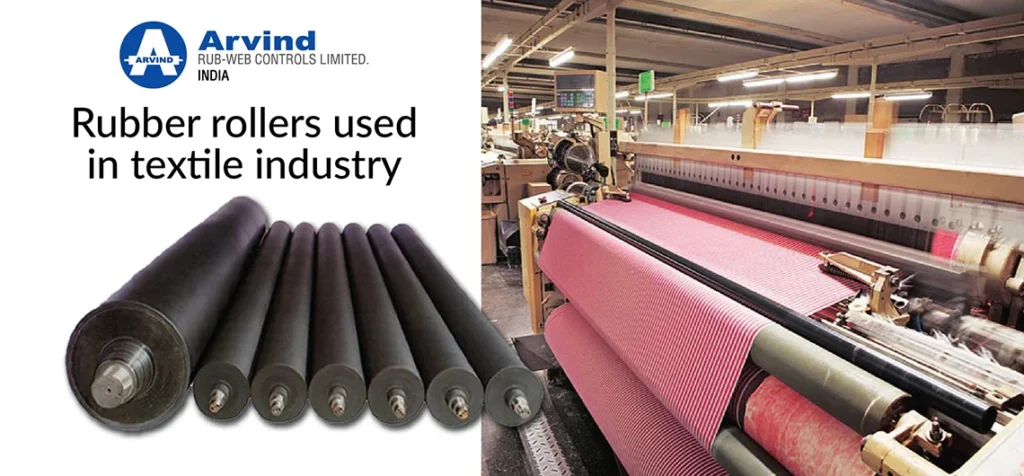

Rubber rollers used in textile industry

The industrial rubber rollers are designed and engineered for a wide range of manufacturing processes. In this industrial blog, we are going to highlight textile rubber rollers, their unique features, and their application in the textile industry. The manufacturing industry-centric rubber rollers for the textile industry are designed for applications that require a high degree of contact and holding friction. Furthermore, it is ideal in material processing applications that require a soft touch. The industrial product is usually cylindrical or spherical. It is a mechanized machine that rolls or rotates. Let’s understand this with a few examples, a small spoke less wheel or like a roller or caster. The manufacturing process of textile rubber rollers A typical manufacturing process of rubber rollers for textiles comprises various rubber fabrication steps. It can be carried out by any of the methods, including plying method, extrusion, casting, and die press. Prominent properties of the rubber rollers for the textile industry Salient features of a quality-driven product As an owner of a textile company, you seek textile rubber rollers that are identified with brilliant features, including easy to install, low maintenance, durable, dimensionally accurate, sturdy design, and easy to install among others. Designs & Dimensions Rubber rollers for textiles are available in a wide range of designs and dimensions. Depending on your manufacturing process requirements, you can choose the roller. Processes All the textiles that we see all around us are made up of fibres. The fibres are arranged and knitted in different ways during the production process to manufacture the desired strength, durability, appearance, colour, and texture. Textile rubber rollers are used during the production cycle for different types of processes, including: Types of textiles Industrial rubber rollers are integral to the textile industry as they are used for a wide range of applications. The product is used for different types of fabrics, including: Conclusion Dimensional accuracy and quality of the product make the difference in production output. Therefore, it makes sense to get the rubber rollers for textile from leading manufacturers of rubber rollers. Never compromise with the quality. There is no dearth of rubber rollers manufacturers in Ahmedabad, India. In this era of technology, you can get in touch with renowned manufacturers from the comfort of your home or office.

How do Rubber Grooved Spreader Rollers support industrial production?

In this industry-centric blog, we are going to focus on rubber grooved roller, its significance for the manufacturing industry, and how it is bringing about a change in the manufacturing setup. Over the years, innovation and technological advancement in the roller manufacturing sector have made the product more effective and dynamic. Traditional products aren’t cost-effective. With ever-rising market competition, companies are looking for technology-driven products that aid in manufacturing, at the same time cost-effective in nature. The rubber grooved spread roller in Ahmedabad is manufactured using excellent raw material and the latest tools and technology, the range demonstrates unique features, including uniform grooves, to perform the seamless non-slipping application. In the ensuing sections, we will focus on a wide range of significant issues related to the product with the hope that the blog will expand the knowledge of readers. Properties of the rubber grooved spreader rollers The roller is known in industry circles for various properties, making it ideal for industrial production in various industries. Take a glance at the properties of the roller. Furthermore, the product has the inbuilt competency to overcome and compensate for the small changes in machine precision. Salient features In addition to brilliant properties, the rubber grooved spreader rollers offer numerous salient features, including: Application The rubber grooved roller is a uniquely designed roller manufactured to carry out specific applications in production lines. These include: Amazing benefits The rubber grooved spread roller in Ahmedabad benefits the production process substantially. The production-centric roller is ideal for very thin substrates and supports converters to run these thinner substrates at lower tensions. At the same time helps in higher line speeds for better productivity. Cushioning and resonance of the industrial rubber grooved spreader rollers are achieved with the help of a unique groove pattern design. Owing to this feature, the product is competent to manage delicate films. At the same time, don’t cause any damage during the wrinkle removal process. Industry Given the benefits and properties of the rubber grooved roller, it is suitable for various industries, including: Buy only from recognized rubber grooved spread roller in Ahmedabad Being an owner of a production unit, you search for rubber grooved spreader rollers that are cost-effective, leading to higher production and in turn increased revenue generation. India’s market is flooded with rubber roller manufacturers. Ahmedabad, Gujarat, India is also one of the prominent manufacturing hubs of rubber grooved rollers. While deciding to buy the product from anywhere, consider a few factors: Conclusion Never compromise with the quality. Quality makes a huge difference in the production process. Buy products from established manufacturers. You can take benefits from the online medium. Join hands with Arvind Rub-Web Controls Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber rollers, metal rollers, bow rollers, rubber grooved rollers, air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver among others.

Modern Grinding Machine enabling businesses to multiply production

Manufacturing companies cutting across domains and geographies are streamlining their production line adopting best-of-breed technology and machines and tools. In this era of ruthless competition, manufacturing units should be dynamic. Why? Orthodox methods are not going to facilitate sustaining the competition. On top of that redundant machines and technology need to be restructured. Myopic thinking could prove out to be disastrous for the survival of a business. You might have heard industry stalwarts laying emphasis on keeping abreast with ever-changing market dynamics. Use the latest Grinding Machine Grinding machines for the textile industry has been an integral part of the manufacturing process. Considering its significance, manufacturers globally focus on the latest version that is manufactured using the latest technology and tools equipment. Let’s comprehend it with a simple example. A grinding machine manufactured employing modern technology enables optimized performance and pushes production. Understanding the Machine Those who are directly or indirectly related to the textile industry are familiar with the grinding machine. The cylindrical shape grinding machine is also famous in industry circles as a special-purpose grinding machine. It’s being employed in textile manufacturing companies for grinding a wide range of large-scale heavy and light rubber rollers. Furthermore, it is also being capitalized to grind convex, concave, and a host of other surfaces according to parabolic trajectory. Modern machines are calibrated to accommodate various types of rubber rollers that are integral to textile manufacturing. Crafted to accommodate various types of surfaces, the grinding machine is used to remove the undue material from the job piece. Providing the required precision, the machine brings the roller back to the required dimension and specifications. Here it’s a rubber roller! Build keeping in view the current textile industry scenario, the Grinding machine for the textile industry offers relative feed and positioning movements between tool and job piece. Is there a defined path? This is a technical question. According to experts, there’s a defined geometrical path that is followed by the movements between tool spindle and job piece. Basic Principle of Functioning The grinding machine has an attached electric motor. This electrically operated motor is designed to perform the designated function. It supplies motion power to the grinding wheel supported by a belt and pulley. How does the grinding wheel rotate? Your concern is obvious. Here is the answer. When you switch on the electric motor, its impact triggers the rotation of the motor at defined RPM. Supported by a v-belt and cone pulley, the grinding wheel begins its rotational movement. This is where its application begins. Skilled labour? Since you are an owner of the company, it’s obvious that you are concerned about overhead costings. There’s a piece of exciting news for you. You don’t have to hire any specific labour to operate this machine flawlessly. It’s easy to operate. Any normal labour can run this machine without any hassle. A bit of initial orientation will serve the purpose. A big sigh of relief! Salient Features of Rubber Roller Grinding Machine For Textile Industry Developed capitalizing on innovative technology, the grinding machine grinds job pieces demonstrating immaculate surface and precise dimensions. Dimension and surface quality among others are two important features of a rubber roller. Any deviation could hamper the smooth functioning of a production line. Application Grinding machines for textile industry is acclaimed for seamlessly performing a wide range of applications, including: How to choose a flawless machine This is a pivotal question, often crosses the mind of textile company owners and decision-makers. The technology could save you from many issues. Browse the Google search engine with relevant keywords. Search engine results will come up with relevant pages. Click on the links, browse through the website. Go through the write-up there about the machine. You can speak with their customer care regarding, your queries. Never compromise on quality.

Understanding Flexible Packaging And The Importance Of Rubber Roller

In this packaging industry-centric blog, we are going to highlight flexible packaging, the importance of rubber rolls for flexible packaging, their unique features, and a host of crucial subjects. Moving forward, the definition of flexible packaging assumes significance, helping readers to connect with the blog. Understanding flexible packaging What is flexible packaging? Flexible packaging as the name suggests is made of flexible packaging material. It is a box or container that can be easily changed in shape after being filled or closed. Paper, plastic, film, foil, and a host of similar materials are used for flexible packaging. The innovation-driven industry is at the forefront of packaging, considering the benefits and advantages it brings along with it. Some of the prominent industries that use modern packaging include Food Processing, Consumer Goods, Pharmaceuticals, and Personal Care. From the basics, it’s now time to shift focus toward another core subject of this blog, rubber rollers for flexible packaging. Bow banana roller is one of the most sought-after industrial rollers in the packaging industry. Learning about bow banana roller Since the shape of the roller is similar to a banana, it is known in industry circles as a banana roller. In addition, it is also famous as a metal expander and bows banana roller. It is one of the widely used industrial rollers in flexible packaging. Unique features of the rubber roller In this section, we are going to highlight the unique features of the product. How would you identify a quality-driven product? You can evaluate the product on various standard parameters. These include: In addition, the quality-driven rubber rollers for the flexible packaging industry quickly compensate for minor changes that occur in the machine’s precision due to consistent operation. Application The quality-driven bow banana roller or bow expander for packaging industries is used for a variety of applications in the flexible packaging manufacturing setup. The versatile nature of the rubber rollers for flexible packaging delivers numerous applications, including reducing slack ends, wiping wrinkles, spreading, slit separation, coating batching, and re-winding among others. How does the roller minimize slack ends? Let’s understand this with an example. During the production process, the appearance of slack ends impacts the production output as well as quality. With the industrial roller for flexible packaging, slack ends are reduced substantially. As a result, production output and quality don’t get hampered. Flexible packaging market size and Growth in India According to a leading market research company, the future of the flexible packaging market looks bright, riding on consistent industrial activities, a growing retail industry, and an increase in demand for digitally printed packaging. The research report indicates that the flexible packaging market in India is estimated to grow at aCAGR of 12.6%between 2022 and 2027. As far as the market size is concerned, it is expected to increase by USD 18.65 billion. Positive growth in flexible packaging means increased demand for rubber rollers for the flexible packaging industry. Conclusion Rubber rollers for flexible packaging are changing the fortune of the flexible packaging industry with their applications and impact. Only buy the product from a leading rubber roller manufacturer in Ahmedabad, India.

Applications of rubber rollers for manufacturing industries

A wide range of manufacturing industries globally is drawing benefits from rubber rollers to meet production challenges. Over the years, industrial rubber roller has become an integral part of the production process in a manufacturing setup. In this blog, we are going to highlight the applications of rubber rollers. In addition, we are going to cover a host of other important subjects. Before we move forward, it makes sense to learn a bit about the brilliant product from the perspective of manufacturing industries. Before we move towards the core subject, let’s first highlight the properties of a quality-driven rubber roller by leading rollers manufacturers in Ahmedabad, India. Unique properties of the product In this section, we are going to highlight the properties of the industrial product. Knowledge of these properties will allow you to identify the best product for your manufacturing company, be it a paper, textile, or laminating industry. Here we would like to mention one more unique feature of a quality-driven product. Low maintenance is considered a key unique feature of the product by recognized rollers manufacturers and rubber rollers suppliers. Low maintenance means, you don’t have to worry about the repairs and regular maintenance. It means you are saving a substantial amount required to service and repair the product. At the same time, this feature ensures low downtime. You don’t have to shut down the operation time and again due to the bad quality of the product. Applications It’s now time to move towards the core subject of this blog, the applications of industrial rubber rollers. This section will resolve many of your queries, like why there’s so much focus on rubber rollers in manufacturing industries. How does the product transform the face of the manufacturing industry? Here is the main application of the product: Current Market Size and future forecast Let’s now talk about the current market size and future forecast of the printing rubber rollers. According to Data Bridge Market Research, a leading market research company, the printing rubber rollers market was valued at USD 590.00 million in 2021. While it is expected to reach USD 905.47 million by 2029, riding on the continued demand for printing rubber rollers. The report suggests that the printing rubber roller industry is going to register CAGR of 5.50 % during the forecast period of 2022 to 2029. These facts and figures clearly indicate that the future looks bright and strong for printing rubber rollers. Overall, the rubber roller manufacturing industry is witnessing a positive growth trajectory. Conclusion Rubber rollers are changing the face of manufacturing industries with their unique properties and applications. Only buy the product from leading rollers manufacturers, and rubber rolls Suppliers.

Why should you choose prominent Steel Rollers?

In this business-centric blog, we are going to focus on steel rollers, their applications, and why manufacturing industries should choose prominent steel rollers manufacturers to buy their products. There are ample reasons to do that. In this blog, we are going to touch on a wide range of subjects. The rollers are designed keeping in view their applications in a range of industries. Quality assumes significance here as inferior quality could jeopardize the production process. As a result, companies emphasize the quality of a product. For businesses, it’s important to ensure the quality of the product. A meticulously designed roller is energy-efficient, durable, and reliable. In this write-up, our focus would be to highlight the roller and a pneumatic air shaft. Unique features of steel rollers Here are a few features of a roller: Standard specifications The metallic roller is available in a wide range of specifications. The standard specifications that are most sought after by industries include: Specification The specification may vary from company to company. Few companies also deliver custom-made solutions. Industrial applications The industry-centric steel roller has found prominence in numerous industries for offering a wide range of applications. Here are a few industries that capitalize on the sturdy roller for scaling their business operation: Besides, there are plenty of other industries that capitalize on this industrial product to seamlessly operate their production lines. Let’s move towards another critical subject of this write-up. The shaft offers quality gripping force. Considering its application, the machine is developed and designed with greater structural strength, at the same time, a powerful expansion mechanism is also ensured. Why this feature? Because such features will help the machine handle the heaviest roll weights at high web speeds. Why should you choose credible Steel Rollers Manufacturers? From the basics, let’s now shift our focus to the major subject of this blog, why should you choose credible Steel Rollers Manufacturers? Fail-safe operation The quality-driven steel rollers by credible Steel Rollers Manufacturers are mechanically sturdy, leading to provide fail-safe operations. As an owner of a manufacturing company, like plastic, textile, or packaging, you require a fail-safe operation. Low maintenance cost Quality rollers manufactured by leading rubber roller manufacturers require low maintenance. Subsequently, you don’t have to allocate a budget for maintenance. Low downtime Downtime is consistent in inferior-quality steel rollers. Your manufacturing operation suffers. However, it has been observed that when you install rollers procured from established Steel Rollers Manufacturers your plant suffers low downtime. Spare parts and accessories of the shaft There are a host of sophisticated spare parts that are assembled to form a pneumatic air shaft, these include valve, hose assemblies, protection strip, brass inflator end, inflator chuck, rubber nozzle end, continuous rubber, lug, inflator Chuck, split clamp, inflator Gun and standard inflator stem. What is a custom-made solution? Client’s specific requirements and industry remain at the core of business while working on custom-made solutions. The solution is a bit costly as specific machines and tools are required to manufacture the product. Since it requires the expertise of the highest order and a particular set of machines and tools, only a few hold the competency to deliver custom-made products. You can connect with Arvind Rub-Web Controls Ltd., a globally famous rubber roller manufacturer to get the specific kind of steel rollers.

Steel Rollers: Importance and benefits of steel rollers

The rollers are designed keeping in view their applications in a range of industries. Quality assumes significance here as inferior quality could jeopardize the production process. As a result, companies emphasize the quality of a product. For businesses, it’s important to ensure the quality of the product. Meticulously designed steel rollers manufactured by leading steel roller manufacturers are energy-efficient, durable, and reliable. In this write-up, our focus would be to highlight the roller. Salient features of steel rollers Here are a few salient features of a roller: For in-depth knowledge, you can connect with a popular spreader roller manufacturer. Standard specifications The metallic roller is available in a wide range of specifications. The standard specifications that are most sought after by industries include: Specification The specification may vary from company to company. Few companies also deliver custom-made spreader roller. What is a custom-made solution? Client’s specific requirements and industry remain at the core of business while working on custom-made stainless steel roller. The solution is a bit costly as specific machines and tools are required to manufacture the product. Since it requires the expertise of the highest order and a particular set of machines and tools, only a few hold the competency to deliver a similar solution. Industrial applications The industry-centric steel roller has found prominence in numerous industries for offering a wide range of applications. Here are a few industries that capitalize on the sturdy roller for scaling their business operation: Besides, there are plenty of other industries that capitalize on this industrial product to seamlessly operate their production lines. Never settle for quality Quality makes all the difference in the production process. Subsequently, it makes sense to buy a product only from some genuine and prominent steel rollers manufacturers. A quality-driven product streamlines production and helps meet production goals. Therefore, being a businessman or someone occupying a senior position in a manufacturing unit, it is your responsibility to ensure that your company procures only genuine bowed rollers from a leading rubber roller manufacturer. Custom-made rubber roller A few companies hold expertise to deliver custom-made steel rollers. Rich professional experience and state-of-the-art infrastructure combined with the incredible domain expertise of engineers and technicians help famous steel roller manufacturers to design custom-made solutions. Production setup varies from one manufacturing company to another. As a result, industrial rollers’ dimensions vary from company to company. In such a scenario, custom-made solutions assume significance. In this era of technology, finding a custom-made solution isn’t a big challenge as from your office or home premises, you can find out the leading industrial roller manufacturer that holds the expertise to manufacture custom-made industrial steel rollers. Hit the search engine with a keyword, for example, industrial spreader roller, steel rollers manufacturers in Ahmedabad, India, etc. Conclusion A genuine spreader roller has the potential to scale your production process, cutting down overhead costs. For a businessman, this is an ideal situation. Money saved is money earned.

How to choose stainless steel rollers for your manufacturing company?

With the advancement of technology, stainless steel rollers manufacturers feel empowered as the company continued to engineer innovative rollers. As a result, manufacturing industries are getting the latest stainless steel roller. In this blog, we are going to focus on this manufacturing industry-centric product. Numerous vital issues and subjects related to the industrial product will be highlighted for the benefit of manufacturing industries that draw advantages from the product. So, how to choose a quality-driven stainless steel roller for your manufacturing company? Before we take a deep dive into the crucial subject, let’s understand the industrial product in simple language. Understanding the stainless steel roller For cloth processing machines, ebonite rubber scroll rollers are perfectly fine. Whereas for other web materials, for example, plastic, leather cloth, paper, vinyl, foils, polyester, etc., the ebonite-made rubber rollers are not suitable. Why? Because the rubber roller generates static electricity, at the same time it also damages the web material. Therefore, to overcome these challenges in the manufacturing industry, steel rollers are designed. Now the picture is crystal clear. Why do manufacturing companies prefer steel roller over traditional rubber roller? Unique features of a quality-driven stainless steel roller Your business is your social and corporate identity. You wouldn’t mind spending extra money if you are getting the product of your choice. That meets industry standards and benchmarks. Here are the unique features of the product: For further information about the features, you can get in touch with a prominent steel rollers manufacturers. Applications The stainless steel roller is used for a wide range of applications, including: Besides, the product offers plenty of other applications, you can connect with an established industrial manufacturer for detailed info. Industries drawing benefits from the steel roller The manufacturing industry-centric steel rollers has found usage in numerous industries, including: Custom-designed product A few manufacturing companies require custom-designed products as their business requirement is specific. Traditional and standard roller designs don’t meet their requirement. So, what’s the way out? Is there any solution for such manufacturers? Yes. To meet the specific requirements of such manufacturers, a few prominent steel rollers manufacturers in Ahmedabad, India hold professional expertise to deliver custom-made solutions. How to find a trusted stainless steel scroll roller? In this era of technology, finding a reputed and trusted scroll roller manufacturer isn’t a big challenge. It is just a click away. Hit google with a relevant keyword, like stainless steel roller in Ahmedabad. The search engine will come with tons of results in the form of web pages. Click on the first few pages. Browse the website of the company thoroughly. If you have any doubts or questions, you can connect with the customer support team. Only when you are convinced, place your order. Start exploring the innovative range of Arvind Rubbers. The company has created a respectable position in industrial roller manufacturing industry, driven by quality and innovation.

How to choose a stainless steel scroll roller for manufacturing?

With the advancement of technology, stainless steel scroll roller manufacturer feels empowered as the company continued to engineer innovative rollers. As a result, manufacturing industries are getting the latest stainless steel scroll roller. In this blog, we are going to focus on this manufacturing industry-centric product. Numerous vital issues and subjects related to the industrial product will be highlighted for the benefit of manufacturing industries that draw advantages from the product. So, how to choose a quality-driven stainless steel scroll roller? Before we take a deep dive into the crucial subject, let’s understand the product in simple language. What is a stainless steel scroll roller? For cloth processing machines, ebonite rubber scroll rollers are perfectly fine. Whereas for other web materials, for example, plastic, leather cloth, paper, vinyl, foils, polyester, etc., the ebonite-made rubber rollers are not suitable. Why? Because the rubber roller generates static electricity, at the same time it also damages the web material. Therefore, to overcome these challenges in the manufacturing industry, stainless steel scroll rollers are designed. Now the picture is crystal clear. Why do manufacturing companies prefer stainless steel scroll roller over traditional rubber roller? Unique features of a quality-driven industrial roller Your business is your social and corporate identity. You wouldn’t mind spending extra money if you are getting the product of your choice. That meets industry standards and benchmarks. Here are the unique features of the product: For further information about the features, you can get in touch with a prominent stainless steel scroll roller manufacturer. Applications The stainless steel scroll roller is used for a wide range of applications, including: Besides, the product offers plenty of other applications, you can connect with an established industrial manufacturer for detailed info. Industries drawing benefits from the roller The manufacturing industry-centric stainless steel scroll roller has found usage in numerous industries, including: Custom-designed product A few manufacturing companies require custom-designed products as their business requirement is specific. Traditional and standard roller designs don’t meet their requirement. So, what’s the way out? Is there any solution for such manufacturers? Yes. To meet the specific requirements of such manufacturers, a few prominent companies in Ahmedabad, India hold professional expertise to deliver custom-made solutions. How to find a trusted stainless steel scroll roller? In this era of technology, finding a reputed and trusted scroll roller manufacturer isn’t a big challenge. It is just a click away. Hit google with a relevant keyword, like stainless steel scroll roller in Ahmedabad. The search engine will come with tons of results in the form of web pages. Click on the first few pages. Browse the website of the company thoroughly. If you have any doubts or questions, you can connect with the customer support team. Only when you are convinced, place your order. Start exploring the innovative range of Arvind Rub-Web Controls Ltd. The company has created a respectable place in industrial roller manufacturing industry, driven by quality and innovation.