Why do manufacturing companies use the Banana Roller?

In this business-centric blog, we will focus on important subjects, challenges, and issues related to industrial bowed rollers. Any idea why it is curved in design? There’s a technical reason behind its composition and design. The curved form of the roller leads to an expansion effect with the support of the wrap angle. The product is a classic example of a combination of technology and innovation. A few of its application comprises separation of slit webs on the winder and removal of baggy centers among others during the production process. This short write-up will help you to expand your knowledge about the product. Salient properties and features of the rollers The industrial product has been a game-changer for numerous companies as it depicts amazing salient features, including: In addition, the roller has a few other important features, for instance, abrasion-proof rubber coating. Similar kind of features ensures an investment worth making. Excessive friction with the finished film and goods leads to the wear and tear of the product. High-quality rubber coating ensures the durability of the product. Application and use of the roller The business-centric roller has been enabling numerous manufacturing companies to scale their production lines and in turn business. Here are a few prominent applications of the amazing product: Industries employing the Bowed Roller In this era of ruthless competition, manufacturing companies are leaving no stone unturned to withstand the market competition and stay ahead of competitors. The emergence of the industrial roller has helped plenty of companies to streamline their manufacturing process. Here are the prominent manufacturing industries employing the manufacturing industry-centric rollers: Maintenance It is a heavy-duty roller. The product doesn’t require any kind of professional training to install and deploy the product at the production lines. Any unskilled person can operate and install the product with minimum guidance. The technology-driven roller is almost maintenance-free. This range of rollers can be easily operated in dry as well as in the wet environment. It is apt for environment and processes where webs are guided without wrinkles. Tailor-made designs There are a few Banana Roller Manufacturers in Ahmedabad, Gujarat that holds expertise in delivering custom-made solutions. Arvind Rub-Web Controls Ltd. is a leading manufacturer, supplier, and exporter of a wide range of industrial rubber rollers. Specifications and designs are customized to match the requirements of the customers. Expertise in the domain drives us to manufacture tailor-made Bow Banana Roller. Shape, customized to match the requirements of the client. Let’s join hands for a mutually beneficial partnership. Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, grooved rubber roller, bow banana roller, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

Why do manufacturing companies use air shafts?

In this business-centric blog, we are going to focus on an important product, the air shaft. Before we move forward, understanding its fundamentals makes sense as it will help us to understand the subject better. Getting familiar with the Air Shaft The product is also known as air bars or air mandrels. It is extremely popular in the manufacturing process for fitting into a core onto which different materials are wound, including paper, card, and plastic. The air shaft has become an integral part of many industries owing to its outstanding features and capabilities. It is embedded with brilliant features, including a slotted shaft, rubber bladders, hard and ground steel cage with a ball gripper. Therefore, it is one of the most sought-after tools in production lines of a wide range of manufacturing industries. Talking about its main objective, it has been engineered to fit into a core perfectly and get expanded. Leading it to gain fast and firm attachment. In addition to this, it can be easily deflated to facilitate easy withdrawal of the shaft, when the winding of the product is complete. Salient features The manufacturing industry-centric machine is identified with numerous features, including: Multitube air shaft The excellence-driven product is famous for offering the best gripping to a wide gamut of cores. It is tailor-made for 5 tubes out of 8. Its dimension may vary from company to company. Furthermore, air shaft manufacturer in Ahmedabad, India also offers the facility of custom design. Application Industries using the product There are several industries that use multi-tube air shafts, including: Mechanical expandable shaft It falls under the category of non-pneumatic shafts. The product is engineered to meet the high-speed and heavy load parameters. Coming to its integral components, these include steel lugs, ratchet, slotted pipe, and brass cam among others. Applications Industrial use The mechanical expandable shaft has been used in a wide range of industries. These include: Maintenance of the air shaft As an owner of the company, your top priority is to procure a product that is cost-effective, durable, and requires low maintenance. While making a purchase make sure to enquire about critical features. Ultimately, the product is going to impact your business. Therefore, no compromise on quality. Summary The quality-driven air shaft is a game-changer for several industries. In this age of technology, finding a reliable manufacturer isn’t a big challenge. Hit the search engine and browse the websites of famous manufacturers. Let’s join hands for a mutually beneficial partnership Join hands for an excellent collaboration Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, grooved rubber roller, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

How does the guide roller help the manufacturing companies?

In this industry-centric blog, we are going to highlight an important product, a guide roller, its importance, salient features, etc. As we move forward and elaborate further on the vital subject, it makes sense to understand the basics of the product. What is a guide roller? The guide rollers are sophisticated rollers designed to point or guide an object in a specific direction. Because it acts as a guide, it is called a guide roller. Coming to the objective of the product, the purpose of the guide roller is to ensure the integrity and alignment of a particular item or product as the latter is in motion. The industrial product is cylindrical. Because of their precise design and essential features, it is suitable for several applications during production. This topic is extensively covered in the following sections. Unique features of the product Industry experts have termed the product as an exceptional development for manufacturing companies as its salient features allow flawless production. Here are the unique features of the product. In addition, the roller has a few other important features, for instance, abrasion-proof rubber coating. Similar kind of features ensures an investment worth making. Excessive friction with the finished film and goods leads to the wear and tear of the product. High-quality rubber coating ensures the durability of the product. Application In this section, our focus will be on an important subject, the application of the product. Manufacturing companies employ the roller for a wide range of applications at their site. These include: Types of Guide Rollers The product has been categorized into different types depending on the materials used to manufacture the roller. These include: Industries using the product A few industries that employ the product in their production line for a wide range of applications. These industries include: Conclusion As the guide roller helps in realizing various important applications, it is vital to use only a quality-driven product. There are numerous guide rollers manufacturers across Gujarat. However, everyone doesn’t hold the expertise to fabricate a flawless industrial roller. In this era of technology, feel empowered as you have the option to explore numerous manufacturers. Get in touch with the reputed and established companies. Browse their websites comprehensively. Also, don’t forget to ensure their market credibility. Custom-made A few companies across Gujarat hold expertise in manufacturing custom-made products. If your business requires a specific dimension, design, you can get in touch with these experts. Join hands for an amazing future Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, guide rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, grooved rubber roller, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

What is an air shaft, and what are its benefits for manufacturing companies?

Over the years technology has evolved enormously, leading to drastic changes in manufacturing processes. Redundant technology hardly serves any purpose. In contrast, it increases overhead expenses. As a businessman, your priority is to minimize overhead costs. Therefore, it makes sense to use the latest technology. Continued advancement in technology is enabling industry-centric products, like air shafts to be leaner. In this short blog, we will highlight air shaft, its benefits for manufacturing industries, and a host of other significant issues. As we move forward, it makes sense to learn the basics about the product. Learning about the product Do you have any idea about this product? In simple language, it is a metallic tube. In industry circles, it has also become popular as air bars or air mandrels, or an air expandable shaft. The important product is designed and configured to adjust to the speed of variations and different core widths. An exceptional product is identified with a few salient features, including its capacity to run at high speed without letting users spend time repositioning. The distinctive lug-type design allows exceptional gripping and core centering. Another unique feature of an industry-centric product is that its cores can be easily handled, which are devoid of uniform inside diameters. The objective of the machine Coming to the objective of the air shaft, when it is fitted onto a core, it can be easily expanded allowing you to get the quick attachment. For further information, you can get in touch with a few leading air shaft suppliers. Only a prominent air shaft supplier should be trusted when it comes to quality. Quality makes all the difference in today’s world. Salient features of the manufacturing-centric product From basics, let’s now head towards another vital section of this business blog. A product is as good as its unique features. Therefore, whenever, you decide to buy this product, don’t forget to enquire about its salient features. It consists of several beneficial features, such as a slotted shaft rubber bladder, hard and ground steel cage with a ball gripper that makes it one of the best tools. Application The industry-centric product offers numerous applications to a wide range of industries. Here are its major applications: Industry Many of the key issues have been elaborated on in this short write-up. Let’s now talk about its industrial use. Here are the industries using the product. Conclusion It’s an investment worth making. However, as elaborated earlier quality makes all the difference. Never compromise with quality. Only prefer a quality-driven product manufactured by a leading air shaft manufacturer and air shaft supplier. Let’s connect for a mutually beneficial collaboration Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders) air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

What are Air Chucks and their applications?

Air chucks is an engineering product offering a wide range of applications to numerous industries. In this business-centric blog, we will focus on a few important subjects directly related to the product. At the outset, it makes sense to learn about the product in simple language. Understanding Air Chucks The small yet important machine is a holding component that has the competency to grasp a wide range of centers in manufacturing processes. Mount it on the shaft with ease! Coming to its installation, and detachment, any employee can easily install and commission the product. You don’t require any professional training to use the product. Similarly, the product can be easily detached when worn out. The quality of the product can be examined from its competency of core grip for light and heavy load. This product provides a simple and lightweight solution for a core holding. It easily mounts on the shaft and ensures that the core remains damage-free. In the following sections, we will be highlighting its features and applications among others. Salient features of the product This industry-centric product is identified with a few salient features. These include: Furthermore, the product is safe to use as it causes damage to the centers. Applications Talking about the application, this product has been designed for an exclusive range of applications, including: In addition to the above applications, the vital product is also suitable for low force activity. Industries benefitting from the product The product is designed for a wide range of industries. A few prominent industries include: How do industry air chucks help the paper industry? With a movable head and a rubber base, the product provides excellent stability during applications. To manufacture paper from the pulp, air chucks are required. Base material pulp is subjected to a wide range of chemical and mechanical processes, before eventually turning into sheets. It includes the wood, chemical, and mechanical procedure that turns wood into sheets of paper. Quality Control Quality makes all the difference in the manufacturing realm as it directly impacts the production and in turn business goals. Therefore, as a manufacturer, if you are planning to enter into export and become a leading exporter of air chucks, then emphasize quality. By implementing a robust “Quality Control Policy”, you can ensure the quality of your range of products. Customization Industry air chucks Industry Air Chucks are available in various standard specifications. Furthermore, a few companies offer customization services. If your industry requires special kinds of dimensions, specifications of industry air chucks, then you require customization solutions. Do you have any idea about it? What is a customization solution? Solutions that are specially designed for an industry or made according to the requirements of a customer are called customized solutions. In this era of technology, finding a customized solution isn’t far away. It is just a click away. In this sense, hit the google search engine with a few keywords. Search engine will show page results, browse these pages and read the website comprehensibly. In case, there’s any doubt, speak with the customer care or concerned department. However, we recommend that never compromise with the quality. Only buy from an established company. Connect with the market leader Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders) air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

How does Silicon Rubber Roller help in the manufacturing process?

The industrial Silicon Rubber Roller is designed to optimize release, reduce friction, wear and abrasion. As indicated by the introductory lines, in this manufacturing industry-centric blog, we will focus on an important product, Silicon Roller. To begin with, it makes sense to learn about the fundamentals of the product in the beginning as it will help the readers and unawares to grasp the subject brilliantly. Learning about the Silicon Roll The Silicon Rubber Roller is a highly active adsorption material. It is fundamentally an amorphous material. A metallic rod is at the core; it has a covering of sturdy silicon rubber. Why silicon-made material? What is so specific about the covering? Silicon is insoluble in water, any kind of solvent. It is non-toxic and tasteless. In addition to this, it is stable in chemical properties, at the same time, it doesn’t react with any substance. Strong base and hydraulic acid are two exceptions. Properties and characteristics of the Silicon Roll An ideal product Coming to its properties, the silicon roller’s electrical insulation performance doesn’t get affected by dampness, rise in temperature, frequency change, etc., therefore, making it ideal for the manufacturing process. Designed for high-pressure applications The product is tailor-made for high-pressure applications since it has a few carbon atoms. No adverse effect on users Workers who are part of the manufacturing process don’t have to worry about the hazards as the product doesn’t pose any threat or adverse effect on the human body. At the same time, it displays amazing physiological inertia and physiological aging. Salient features of Silicon Roller A product is identified with its salient features, like efficiency, performance, and durability during use. Sturdy material lends excellent features to the product, including brilliant resistance to chemicals, at the same time, it resists cuts and abrasion. Talking about electrical properties, a brilliant product offers excellent resistance to heat, ozone, and moisture. Applications The quality-driven product is designed for a wide range of applications in manufacturing processes, including: Industry A quality-driven compound offers ideal mechanical and physical properties for a longer endurance even in extreme and trying conditions, at the same time provides superior release properties. Furthermore, the distinctive combination of the silicone formula and bonding system enables in developing and maintaining physical properties even at extremely low temperatures. Instruction for use of Silicon Rubber Roller In this section, readers will be suggested a few instructions to use the Silicon Roll. At the start At the time of starting the machine for heating, ensure that the rubber roller operates normally. At the shutdown While shutting down the machine, ensure that the residual temperature delay remains usual. Do not shut the machine directly This is again an important instruction. Never shut down the machine directly as the residual temperature delay is generally set at 40-50 minutes. Power failure In case there is a power failure or sudden breakdown due to any untoward reason, put the machine immediately on gloves. Customization A few Silicon Rubber Roller manufacturers in Ahmedabad hold expertise in offering customized solutions. In case, your industry has a specific requirement for Silicon Rubber Roller, get in touch with such companies. If you are looking for a quality-driven Silicon Rubber Roller, then end your search with Arvind Rub-Web Controls Ltd.

What is a rubber roller, and its benefit for manufacturing industries?

In this industry-centric blog, we will be focusing on an important industrial product, the rubber roller, its benefits and advantages, and rubber roller manufacturer among others. Over the years technology has evolved a lot, helping manufacturing companies to streamline their production process and get better. Rubber rolls manufacturing hasn’t remained unaffected. Over time, it has also changed. At the outset, it makes sense to understand the basics of the product. It will help us to connect with the blog better. Learning about the rubber roller Simply put, a rubber roller is a product comprising of an inner round shaft made of iron, steel, aluminum, allow, or carbon fiber. This scientifically designed roller is covered by an outer layer of elastomer compounds. As far as the outer layer is concerned, it is generally manufactured from a polymer, like polyurethane, silicone, EPDM, neoprene, and natural rubber. Salient features of the product This product is identified with numerous salient features, including: For further information, you can connect with any leading or famous rubber roller manufacturer in Ahmedabad. Furthermore, the product also offers the following properties: Physical properties and other characteristics of rubber rolls According to experts, the product is identified with numerous physical properties and characteristics. It occurs due to the molecular structure. Rubbers are fundamentally polymers with high elastic nature, the result of crosslinking of long polymer chains into amorphous structures. Their molecular structure helps them resist any kind of damage during application. Therefore, it is a durable product. Hardness: The harder the surface of the rubber rolls, the tougher it is to compress or penetrate or distort. Also, it resists any attempt to deform it during application. Abrasion resistance: It is an abrasion-resistant product. Impact resistance: This product repels any kind of impact due to a sudden fall or hit. The elasticity of the rubber material makes it possible. Compression set: The product shows high compression set during application. Low compression set means, it will lose resiliency fast. Tear strength: This is again an important property of the product. It shows the competency of the rubber lining to endure the application of tensile forces. Endures low temperature: The product is tailor-made to endure low temperature and therefore protects itself from becoming brittle. Aging resistance: Over time, due to use, the product loses strength and elasticity kind of characteristics. However, an excellent product depicts high aging resistance. Thus, has high durability. Industrial applications Let’s now move towards the applications. Industries using the product The rubber rolls are used in numerous industries, including: A leading rubber roller manufacturer has the competency to deliver your industry-centric product. Join hands with Arvind Rub-Web Controls Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber rollers, metal rollers, bow rollers, air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver among others.

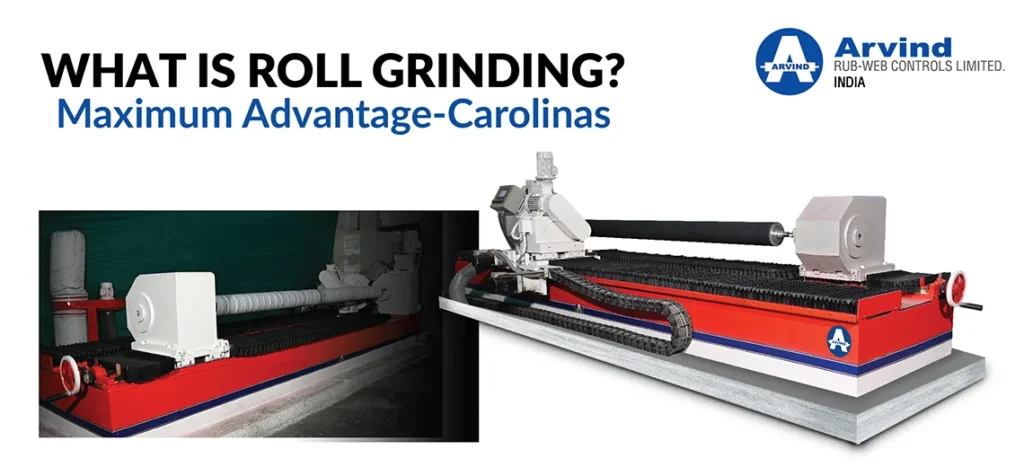

What Is Roll Grinding? | Maximum Advantage-Carolinas

Over the years roll grinding manufacturers have shifted towards innovative technology and machines, riding on multiple benefits offered by new-age technology. In this manufacturing industry-centric blog, we are going to focus on a wide range of important subjects related to roll grinding machine. At the outset, it makes sense to define the industrial machine in simple language. It will help readers to relate to the blog in a better way. Learning about the machine What is a roll grinding machine? It is a mechanized machine used for the purpose of grinding industrial rollers. The quality-driven machine is designed for material removal with geometrically non-defined, bonded cutting edges. As far as movement between tool and workpiece is concerned, it is rotational or linear. Each grain of abrasive present on the wheel’s surface cuts a small chip from the workpiece by deformation. The machine has been fabricated to provide relative feed and positioning movements between tools and workpieces. Talking about roll grinding machines, it is a typical method of processing wherein an abrasive wheel plays a key role. The robust wheel is used as a cutting tool. Besides roll grinding, the machine is also competent to carry out many milling tasks. Salient features and properties From the fundamentals, let’s now shift our focus to salient features and properties. In this era of ruthless market competition, Roll Grinding Machine Manufacturers are not leaving any stone unturned to deliver a quality-driven product. Therefore, salient features assume significance. Different essential parts and their features Main machine body Machine table Wheel head Work head Tail head Hydraulic unit Electrical unit Lubrication Unique features Application In this section, we are going to talk about the application of the machine. The roll grinding machine is designed to perform a few special applications. These include: For further information, you can connect with a few Roll Grinding Machine Manufacturers of Ahmedabad, India. Finding a leading machine manufacturer isn’t a tough task in this era of technology. Go to the search engine. Enter a few keywords, like roll grinding machine manufacturers. The SERP will come up with a result. Click on the web pages. Browse the website comprehensively. Get in touch with their engineers and sales team. Never compromise with the quality since your production line depends directly on the quality of the roller. Industrial use The manufacturing industry-centric machine is tailor-made for numerous industries, a few include: Customization A few Roll Grinding Machine manufacturers hold expertise to deliver custom-made solutions. In case, you require a machine with specific dimensions, you can get in touch with a leader like Arvind Rub-Web Controls. Conclusion Quality speaks volume! It does wonders. Never buy redundant machine. Why take an useless risk.

Learning about Silicone Rubber Roller and its uses

Over the years industrial silicon rubber roller has witnessed numerous changes, riding on the emergence of new technology and innovation in silicon rubber roller manufacturing. Considering the significance of innovation, silicon rubber roller manufacturer is leaving no stone unturned. In this blog, we are going to focus on Silicone Rubber Roller, its variants, and its applications among others. At the outset, it makes sense to learn about the industrial roller. Learning about industrial roller Industrial rollers are widely used manufacturing components that are designed to serve multiple applications and functions of facilitating and processing different types of material and product movements in manufacturing or industrial settings. There are different types of industrial rollers. Types of rollers Manufacturing industry-centric rollers have been classified into various types, depending on the coating applied on the metallic core. These include Rubber Roller, Ebonite Roller, Guide Roller, Teflon coated Roller, Glue spreader Roller, HCP Roller, Silicon Rubber Roller, and Nip Noller among others. From the basics, let’s now move to the main subject. Silicon rubber roller Since silicone is a highly versatile material, its various properties are suitable for manufacturing processes. Its flexibility, biocompatibility, and resistance to temperatures, UV light, radiation, and ozone making it ideal for different manufacturing processes. Why do companies choose silicone rubber rollers? Silicone rubber is one of the most sought-after synthetic rubbers across manufacturing industries. Talking about its composition, the product is composed of silicone bonded with hydrogen, carbon, and oxygen. It is cross-linked polymers reinforced with silica. The exclusive synthetic elastomer provides an ideal balance of mechanical and chemical properties, Salient features of the product Silicon rubber roller has numerous unique features making it an ideal product for manufacturing and processing units. Some of these include: Properties of the product As the silicon rubber roller demonstrates unique physical, mechanical, and chemical properties, it is considered an integral part of many manufacturing processes. Here are a few properties of the brilliant product: Flame retardant: It demonstrates high thermal stability. Steam resistant: Since the product offers high thermal stability, it maintains its shape and consistency when exposed to intense temperature and sunlight. Excellent compression set: The product demonstrates a high compression set. Therefore, retains its shape even while facing extreme compression and temperatures. UV and radiation resistance: Silicone has the competency to retain its properties and don’t degrade when exposed repeatedly to UV or any other type of radiation. Adhesion to metal: This product depicts the brilliant property of adhesion to metals, especially during molding and extrusion processes. High tensile strength: The silicone depicts optimized tensile strength, from 200 to 1,500 psi. Chemically inert: Silicon rubber is chemically inert, therefore, it is suitable for the manufacturing process. Applications The industrial roller is custom-made for rolling, polythene, printing, and dyeing plastic composites. It is widely used in lamination plants and MDO Nip rollers. Industry Silicone rubber rollers are suitable for a wide range of industries, keeping in view their unique features. These include: Silicone rubber roller manufacturers continue to use the latest technology to deliver an excellent products for different manufacturing companies. Considering its impact and unique properties, its use is growing exponentially. It is an encouraging sign for the roller manufacturers. Conclusion Quality makes all the difference in the manufacturing process. Therefore, only buy the product from the established silicone rubber roller manufacturers. Join hands with the industry leaders Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber rollers, metal rollers, bow rollers, air expandable shaft, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver among others.

All you want to know about bow expander roller

In this industry-centric blog, we are going to elucidate about an important industrial product, the bow expander. Why it is called so? Since the shape of the product is similar to a bow, it has found its name from there. In the ensuing sections, we will be covering a lot of important subjects related to the product. This blog will further expand your knowledge about the subject. Industries using the product will draw benefits from the product. Design and construction To begin with, let’s share a brief about the design and construction of the bowed roller. The manufacturing-industry-centric product comprises a central beam with a bow in it, while bearings are mounted across the entire roll. At the same time, it is covered with a rubber covering over the bearings. It is also called a spreader roller. A bit about the location of the bow expander roller now. As far as their location is concerned, the product is normally located before nipped rollers. That is before and after coating stations, after size presses, before drive points, and in long web runs. Types of a spreader roller There are numerous types of spreader rolls. The advent of technology and innovation in the field has resulted in many new designs, including: How to measure the dimension? Considering its shape, many of you might be thinking, how do manufacturing companies measure its dimension? According to industry experts, the amount of bow is measured by arc height divided by roll width X 100. Unique features of the bowed roller The bowed roller is identified with unique features that set it apart from the crowd. Here are a few unique features of the product Specifications The specifications of the product vary from company to company, it primarily depends on the type of industry and requirement. Here is the standard specification of the product: Application From the features section, let’s now shift our focus to the application of the product. As the product is versatile, it serves many purposes. A quality-driven product offers applications, like reducing slack ends, wiping wrinkles, spreading, slit separation, coating batching, and re-winding among others. Industries drawing benefits and advantages from the bow expander roller The spreader rolls are integral to many web handling processes as a result the product has found its use in several industries. These includes: Never settle for quality Quality makes all the difference in production. Subsequently, it makes sense to buy a product only from a genuine and prominent manufacturer. A quality-driven product streamlines production and helps meet the production goals. Therefore, being a businessman or someone occupying a senior position in a manufacturing unit, it is your responsibility to ensure that your company procures only genuine bowed rollers from a leading rubber roller manufacturer. Conclusion A genuine bow expander roller has the potential to scale your production process, cutting down overhead costs. For a businessman, this is an ideal situation for a business. Money saved is money earned.