How to identify the quality of rubber rolls?

A wide range of manufacturing companies uses rubber rolls to complete their production process. Before moving forward, its importance assumes significance. In this short and insightful blog, we are going to focus on numerous important issues that are related to industrial rubber rollers. Our core focus will remain on how to identify the quality of rubber rolls. As we move forward, let’s understand the rubber roller. What is a rubber roller? In simple and layman’s language, a rubber roller is a sophisticated machine that comprises an inner shaft or tube. This shaft is made up of metal, like aluminum alloys, iron, steel, and carbon fiber. Choice of material depends on industrial use. This metallic shaft is covered by an outer layer or coating of elastomer compounds. Talking about the coating, the outer layer is traditionally manufactured using polymer, including silicone, EPDM, neoprene, and natural rubber. A rubber roller company has the professional expertise to manufacture, export, and supply a wide range of rubber rolls. Salient features Bow expander roller bowed rollers and textile rubber roller among others are being used in manufacturing industries for various applications. Rubber rolls are identified with the following salient features: While purchasing bowed rollers for your business, make sure these are in line with the market standards. Application of rubber rolls The industrial rubber roll is trusted and relied on for a wide range of applications across different industries. Here are a few applications of the industrial roller. Performance comparison of different material Neoprene roller: This type of roller has numerous fabulous features that make it one of the favourites among manufacturers. It has excellent wear and tears resistance, high fire resistance, and brilliant heat resistance. These features help it to deliver brilliant performance during operation. Rubber Roller: A rubber roller has excellent features. It is resistant to weather, acids, and chemicals. These kinds of rollers have found usage in textile, packaging, and paper among others. Natural rubber roller: These kinds of industrial rubber rollers have excellent elasticity, mechanical strength, brilliant resistance to acids and chemicals. Polyurethane rubber roller: It has exceptional features. High mechanical strength. Resistant to corrosion, aging, oil, etc. In addition, it has brilliant viscosity. It is commonly used in wood and plastic processing. Silicon rubber roller: It is again an example of a brilliant roller product. It has high-temperature resistance, high-pressure resistance, chemical inertness, etc. it’s ideal for packaging and textile and non-woven fabric manufacturing. Let’s connect for a mutually beneficial partnership Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

Why do manufacturing companies use a banana roller?

What is so special about the bowed rollers? Why does a wide range of manufacturing companies use the roller in their manufacturing line? Dear Readers, the above expressions are enough to give a hint about the topic of this blog. In this concise and engaging business blog, we are going to share a few important points related to the product What is a banana roller? At the outset, it’s important to learn about the product. Subsequently, we will move towards other important subjects. In common man’s language, and industrial roller that has a unique design inspired by natural fruit, banana is known as banana roller. In industry corridors, it is known by several other names, including bow rolls, bow expander roller, bowed rollers, etc. According to industry experts, most of the expander rolls are driven by web tension itself. The product doesn’t require any extra drive. Salient features of the roll Moving forward, in this section, our focus will revolve around the salient features of the roll. When you take a decision to buy this product, don’t forget to remember these salient features. These include: In addition, the industrial roll requires low maintenance and demonstrates brilliant durability. Trust the market leaders with proven track-record only There are a few features that vary from company to company. To make the gray picture clear, I would like to use an example. Arvind Rub-Web Controls Ltd., a pioneer in the industry with several firsts to its credit provides an excellent range of rubber expander rollers. Their range of products has been acclaimed for low maintenance, excellent performance, and durability. Do you think an ordinary business-centric roller manufacturer has the potential and technical competency to manufacture an excellent range of rubber expander rollers? The point here is – never take a decision in haste. Haste could jeopardize your production line and in turn business. None of the businessmen wants that to happen. Applications Now coming on to another important feature, applications of the industrial rollers. The rubber expander rollers have found applications in various manufacturing processes. These include: Industries using the banana roller The technically sound rubber expander rollers are being used in a wide range of industries, these include: Custom-made products A few companies in India are offering custom-made rubber expander rollers. If your business requires a tailor-made design to meet your manufacturing process’ demand and challenges, then you are recommended to connect with a company that provides custom-designed solutions. Instead of compromising on specifications, get the precise product, from the expert manufacturers in Gujarat, India. Let’s connect for a mutually beneficial partnership Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

What and why of the air shaft

Why do manufacturing companies rely on air shafts? It is a mechanized device that is helping a wide range of manufacturing companies to meet their different production line objectives and challenges. In this brief and important blog, we are going to focus on key subjects that impact the machine. Air shaft manufacturers across India, including Ahmedabad, Gujarat are leveraging modern technology and machinery to deliver quality-centric airshafts. Learn the basics of the machine What is this machine all about? Why do companies impart excessive importance to these industrial devices? Industrial applications of the machine In this section, we are going to focus on the industrial applications of the technically sound device. Manufacturing companies galore use the machine in their numerous manufacturing processes. It is a device designed and manufactured for handling winding reels in the processing of web-fed materials. Here the example of the printing press assumes significance and aptly suits the machine. The mechanical device is being relied on in various production lines for fitting into a core onto which material, for example, paper, card, and plastic film are wound. The airshaft has been endowed with amazing properties and features. Once it is applied into a core, the machine has the capability to get expanded, when required. Subsequently, realizing a quick and firm attachment. In addition, the machine can be easily deflated. This property helps swift and easy withdrawal of the shaft, once the winding of the product gets completed. Winding and unwinding of rolls: Innovative design lends another excellent feature. The device is perfect for mounting onto bearing housings to facilitate the winding and unwind of rolls of stock material. Minimum downtime: The device needs a minimum of equipment downtime. Therefore, doesn’t impact the production line. Efficient to grip the core: This is another amazing benefit of the machine. It has the efficiency to grip the core, at the same time prevents any kind of damage at the same time gives a positive interface to manage and control the web via motors & brakes. Material Types of air shafts and manufacturing process The device’s raw material varies from air shaft manufacturer to air shaft manufacturer. Keeping in view the demands and requirements of various manufacturing industries and processes, air shaft manufacturers are developing different types of devices. These includes: These could be either lug type or strip type. Machines The mechanical device is suitable for different types of converting machines, for instance slitting machines or slitter rewinder. As far as, its application is concerned, the machine is being used to cut or slit large rolls of material. Material In general, these devices are manufactured using two types of metals: Besides, carbon fiber air shafts are also available in the market. The high-end shaft offers astonishing features Industry The air shaft is being used in: Are you searching for an air shaft manufacturer? End your search with Arvind Arvind Rub-Web Controls Ltd. Let’s connect for a mutually beneficial partnership Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

Why do manufacturing companies require steel rollers?

In this industrial blog, we are going to focus on numerous subjects that are related to steel rollers. Professionals working in manufacturing industries and those who have a deep interest in industrial rollers will get benefits from the blog. This isn’t an ordinary subject. Businesses will draw advantages from this blog. Learn about the rollers As we move forward, let’s understand the basic definition of business rollers. Steel rollers are frequently used for depicting excellent durability and performance in the manufacturing ecosystem. During the production process in a manufacturing company, the roller goes through immense wear and tear. Sturdy steel rollers tolerate the tough situation. What does it mean? It means that the roller will survive longer than an aluminum-made roller. Similar unique features lead to reduced replacements of the rolls and bare minimum maintenance cost. In addition, steel is also preferred over aluminum in manufacturing processes wherein the industrial rollers are subjected to the higher temperature. Industrial rollers are widely used across manufacturing industries for diverse functions. Rollers facilitate and process material and product movement in manufacturing settings. Unique features Steel roller manufacturers across India, including Ahmedabad, are emphasizing on quality of the roll since it affects the production line. The better the quality of the roll, the higher will be the production. Shape Industrial steel rollers are usually in the shape of cylindrical or spherical shape. Applications From the basics of the rolls, now it’s time to highlight the applications. The sophisticated rollers are being used to carry out the following applications in material processing settings: Industrial use Grooved rollers are custom-designed for packaging, distribution, warehouses, manufacturing plants, recycling facilities, etc. Since steel rollers provide numerous benefits during the application, they are being used in a wide range of industries. These include: Custom-designed rollers Steel roller manufacturers generally manufacture standard rollers. A few roller manufacturers have vast experience and modern infrastructure to deliver custom-made rollers. How does that benefit customers? It’s a reasonable question, many of you might be thinking to raise? Why do a few companies require custom-designed industrial steel rollers? Dimensions and specifications of the rollers vary from company to company. Some may require standard sizes whereas a few companies would prefer custom-designed rollers. In this scenario, both the stakeholders enter into a dialogue to discuss modalities about the design, product, and precision. Subsequently, with the latest machines and tools, the roller manufacturer provides a solution. Conclusion If you are planning to procure a roller for your company, we recommend only buying from established and admired manufacturers. The reason is – better the quality of the roller, excellent will be the performance. Finding an ideal roller for your manufacturing process isn’t a daunting task in this era of technology. It is just a click away. That’s right. You can use the internet to access and explore the perfect manufacturer for your manufacturing unit. Even a visit to their plant could be a great step forward. Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), steel rollers, ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

What are important types of Rubber roller covering techniques?

This is going to be an important write-up for manufacturing industries. In this business-centric blog, we are going to emphasize a wide range of rubber rollers covering techniques. Before that happens, let’s understand the rubber roller. What is it all about? Why do manufacturing companies focus on this product? Learn about the rubber roller in simple language When we think about rollers, people generally think about paintbrushes and wiping rollers. That’s not true. Truth is an industrial rubber roller is designed for applications wherein a high degree of contact is required, at the same time holding friction. These are suitable for material processing applications requiring soft touch. Significant features, specifications, and industry Now, let’s shift our focus to another key subject. In this section, we will get to know about rubber roller features, specifications, and Industry. Attributes Applications Industry Rubber roller covering techniques Rubber roller manufacturers across India, including Ahmedabad, India is using various trusted techniques of applying rubber to a metal core. Here are the most used techniques: Traditional wrapping In this type of wrapping, covering begins with cutting the rubber sheet as per the dimensions of the roller. Afterward, the core goes through the lathe for the final finishing. Extrusion method This is also one of the leading covering techniques. In this method batches that can be fed to the extruder are more than enough. There is no need for expensive calendared rubber. Cross-head extrusion For mass production of rubber rolls, cross-head extrusion is one of the recommended methods of covering. Three roll builders This technique is also extremely popular among manufacturers. When the core is ready for covering, the calendared rubber is torn to it. It is applied to cover the width of the roller. Afterward, the third roller comes into the picture and this third roller applies pressure to the rubber sheet. Driving the rolls to help in turning the core. Subsequently, wrapping rubber from the roll onto the core. Conclusion Rubber rollers are leveraged for a variety of purposes in manufacturing units and companies as mentioned in this blog. Since quality is important, we recommend you buy the roller only from leading manufacturers. Why? Better the quality, higher the production. Let’s connect for a mutually beneficial partnership Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

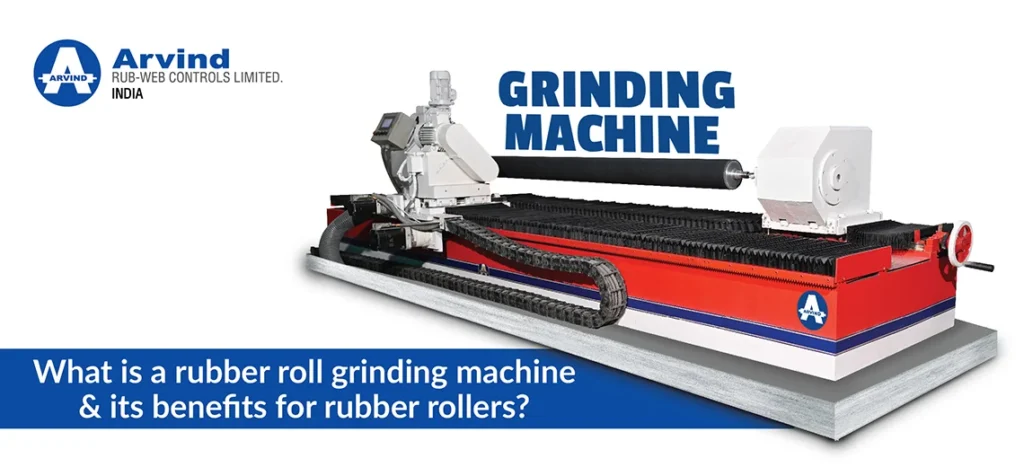

What is a rubber roll grinding machine and its benefits for rubber rollers?

Over the years, the manufacturing industry has witnessed sweeping changes. Machines and technology which were once the core of manufacturing are no more in use as these have become redundant. Instead of helping industry, outdated machines and technology increase production costs. Therefore, the use of the latest technology has assumed significance. Rubber roll grinding machine has also changed dramatically in the last few years riding on innovation and modern technology. In this manufacturing industry-centric blog, as it has been indicated through introductory lines, we are going to focus on a sophisticated machine, its significance, benefits, etc. Before we move forward, it makes sense to learn about the machine which is transforming the rubber roller manufacturing industry. What is a grinding machine? It is a mechanized machine used in the process of grinding. With an abrasive wheel, the grinding process takes place. Thus abrasive machine acts as the cutting tool. A small chip from the workpiece gets cut by each grain present and embedded in the abrasive wheel’s surface through shear deformation. Functions and applications of the grinder may vary from manufacturer to manufacturer although fundamentals remain the same. This machine was developed keeping in view certain tasks and challenges wherein heavy and large workpieces can be loaded for processing. Why does roll require grinding? Grinding is an exclusive process. It is carried out to finish workpieces that must yield brilliant surface quality. Means? It means the workpiece must demonstrate low surface roughness and high accuracy of dimension and shape. Roll length The rubber roll grinder has the competency to grind rolls of different lengths and dimensions, ranging from a few centimeters to six meters. The finished product has an incredible finish, ready to be used in a wide range of industries. Best rubber roller grinding machine India offers an excellence-driven machine. Construction of a rubber roll grinder As far as the configuration of a rubber roll grinding machine is concerned, it comprises: Let’s now for a moment, bring our focus on the construction of a grinder. As far as the external construction is concerned, the industrial grinder comprises: Salient feature How to determine the speed of the machine? This is an important subject as it determines the rate of production. Here is the answer. The speed is determined by the machine manufacturer and also depends on the diameter. The grinding head is engineered to travel across a fixed length of the workpiece. Also, it can be the other way round, the workpiece (rubber roller) can be maneuvered and the grinding head stays in place. Some of its salient features comprise: Application and benefits Now, it’s high time to focus on the application part, one of the most important sections. Here are the applications of the brilliant machine Industry There are numerous industries and sectors that draw benefits from the machine. These include: Summary The quality of the machine is of prime importance as the roller that goes through grinding plays a significant role in the production line of a manufacturing company. That’s why it is important to buy a grinding machine from a reputed manufacturer. Let’s join hands Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

What are the benefits of rubber rollers in steel industries?

In this era of a fast-paced world, manufacturing industries are leaving no stone unturned to produce a flawless product range. An industrial rubber roller has assumed significance in a wide range of manufacturing processes. In this blog, we are going to emphasize industrial rubber rollers and how the component lends various benefits to steel industries. Before taking a deep dive into the prominent subject, it makes sense to understand the rubber roller in simple language. Besides industry people, this blog is going to increase the knowledge of general readers. Learning about the Rubber roller Industrial rubber rollers are designed to carry out numerous applications in a wide gamut of manufacturing processes. The simple yet important device facilitates the processing of material and its movement in industrial settings. Properties and applications of industrial rubber rollers depend on the material of the roller. It is predominantly classified into three types: Besides business-centric rubber rollers, other industrial rollers include guide rollers, bowed rollers, steel rollers, etc. Significance of a metallic and steel roller This type of specially designed roller is suitable for sustaining heavy component movement as it is competent to carry a large bearing load with bare minimum touch. This type of roller is available in straight or crowned geometry. Benefits Properties of a standard steel industry-centric rubber roller are: Applications The industrial roller has been used for a wide range of applications. Here are a few prominent applications of a rubber roller: Custom industrial rollers Barring a few, every steel manufacturing company requires some specified rollers with predefined specifications. Industrial custom-made rollers assume significance here. A few companies in Gujarat, India are competent to manufacture custom-made industrial rollers. As an owner of a steel manufacturing company or a decision-maker working in a steel manufacturing unit, you look for a roller that perfectly suits the dimensions required at your production setup. Any untoward deviation from specifications could hamper production and quality. Therefore, companies lend emphasis to custom-made rollers. Arvind Rub-Web Controls Ltd. is a reputed name in industrial rubber rollers with expertise in custom-designed rollers. Summary Quality makes all the difference in production. Industry experts are of the opinion that the better the quality of the roller, the higher the production. Most of the famous names in manufacturing have a separate quality control department. The sole objective of this kind of unique department is – to ensure quality. Let’s connect for a mutually beneficial collaboration Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

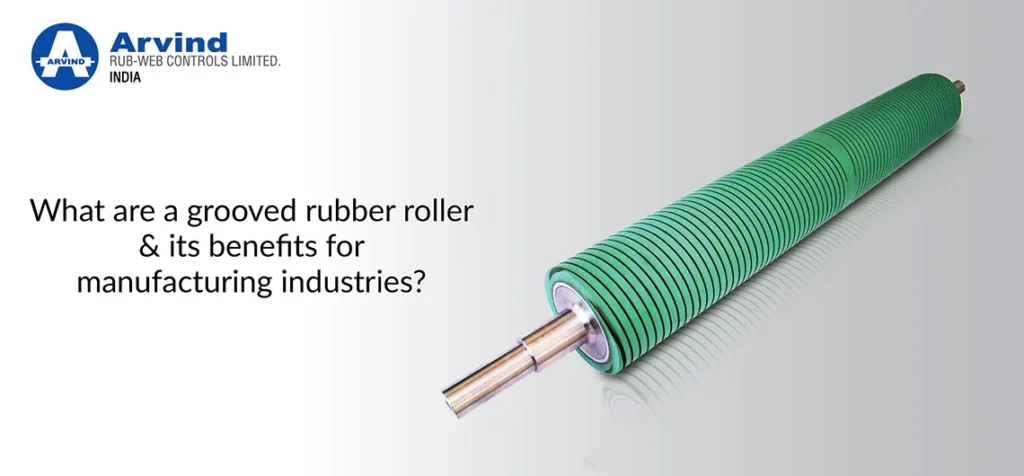

What are a grooved rubber roller and its benefits for manufacturing industries?

In this business-centric blog, we are going to focus on a very important product, a grooved rubber roller. Over the years, this product has become an integral part of numerous manufacturing industries for its excellent applications. Before we move forward and take a deep dive into the crucial subject, let’s learn about the roller. Learning about the roller These are in fact industrial rubber rollers having distinctive groove patterns on the rubber surface. The groove pattern facilitates in developing cushioning and resonance. It is a distinctive feature that helps these rollers become competent to handle delicate films. In addition to this, this characteristic of the product helps in the process of wrinkle removal without causing any damage. This is also famous as a rubber grooved spreader roller. Design and dimensions The grooved roller is available in various designs and dimensions. Based on your industrial requirement, you can choose the product. Spiral and straight grooved rollers are among the most sought-after designs in industry circles. You can get in touch with leading rubber rolls manufacturers for your requirements. Properties Here are the properties of the product that show why our rubber grooved spreader rollers are the best: Salient feature Here are the key features of the product that reflects our expertise and justify why our rubber grooved spreader rollers are the best: Applications Here are the applications of the product: Industrial use The business-centric product has been employed in numerous industries, including: How to choose the perfect product? A product you are planning to buy for your manufacturing company shouldn’t be inferior. It should match industry standards, dimensional accuracy and matches your industry’s requirements. Custom-made design A few companies require specific designs and dimensions to meet their requirements. For such companies, custom-made design is suggested. Some leading companies like Arvind Rub-Web Controls Ltd. are professionally qualified to develop custom-made designs for your manufacturing company. Their expert and dexterous team with vast experience assesses and examines your requirements at the outset. Afterward, their expert engineers and technicians manufacture your kind of roller using a modern facility. Summary The quality of the roller makes all the difference. Therefore, never compromise with the quality. While choosing your product make sure it adheres to various quality standards. In this era of technology, finding a brilliant manufacturer isn’t a big challenge. Use Google to explore manufacturers. Choose the best only! Let’s join hands for a mutually beneficial partnership. Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, grooved rubber roller, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.

Why Arvind Rubber is globally famous as a pioneer of rubber rolls?

Over the years, the manufacturing industry has witnessed numerous changes. Emerging technology and innovation have been the building blocks of the sector. Manufacturing industries irrespective of domain expertise are drawing the advantages and benefits of modern technology to scale their business. In this blog, our focus will be rubber roller. In addition, we will focus on the significance of Arvind Rub-Web Controls Ltd. in redefining the rubber rolls manufacturing sector. Before we move forward, let’s understand the rubber roller. Learning about the Rubber roller What is an industrial roller? It is a metallic shaft, cylindrical in shape. This metallic shaft can be fabricated using aluminum, steel, alloys, and a host of other metals, depending on the business requirement. Talking about the outer layer, it is fabricated from a wide range of polymers, including polyurethane, silicone, EPDM, neoprene, and natural rubber. Properties of a quality rubber roller These properties make the rubber roller an ideal product to handle finished goods in production lines without causing any damage to the product. Salient feature Here are the key features of the product that reflects our expertise and justify why our rubber grooved spreader rollers are the best: Why Arvind Rubber is the pioneer of rubber rolls manufacturing? With more than four decades of professional experience in the armory, Arvind Rubber has created a remarkable niche in the market. Over the years, the company has enabled hundreds of customers from diverse domains in fulfilling their business goals. 100+ innovative product range demonstrates the competency and expertise of the company. Its clientele ranges from small-sized manufacturing companies to a giant-sized conglomerate. Types of rubber/ ebonite rollers Applications Industries Industries using the rubber roller being manufactured by the company comprise: Unique features of the company Here are a few unique features of the company that makes it stand out from the crowd: Custom-made rubber rolls As a unique rubber rolls manufacturer, Arvind Rub-Web Controls Ltd holds the expertise to deliver custom-made rubber rolls. A team of professionally qualified engineers and technicians are experts in delivering custom-made solutions for various types of manufacturing industries. This custom-made design team is headed by a senior engineer with vast industry experience. Under his leadership, the team looks into the requirements of the customers. Afterward, a detailed design is developed. Upon approval from the client, the production team begins manufacturing.

Why Arvind Rubber is the pioneer of rubber rolls manufacturing?

With more than four decades of professional experience in the armory, Arvind Rubber has created a remarkable niche in the market. Over the years, the company has enabled hundreds of customers from diverse domains in fulfilling their business goals. 100+ innovative product range demonstrates the competency and expertise of the company. Its clientele ranges from small-sized manufacturing companies to a giant-sized conglomerates. Their rubber roller range comprises press roller, felt guide roller, press guide roller, size press roller, bottom press roller, etc.