What is a Rubber Roller? What is its importance?

Manufacturing industries across the globe rely on rubber rollers to seamlessly conclude myriad applications. Before making a deep-dive into the significant industrial subject, it’s pertinent to comprehend the term Rubber Roller in the layman’s language. What is a Rubber Roller? A rubber roller is a sophisticated machine comprising a metallic inner round shaft or tube which is covered through an exterior layer of elastomer compounds or rubber. The inner metallic shaft could be of steel or aluminum or any other industry-specific metal, depends on the rubber roller manufacturer. Coming back to rubber roller layer, the outer layer is generally manufactured using a premium-quality polymer, including polyurethane, silicone, EPDM, neoprene, and natural rubber. Industrial rubber rollers, like rubber bow roller, are being used in various applications requiring a high degree of contact and holding friction. Besides, the industrial product is also used in material processing applications wherein a soft touch is required. Types of Rubber Rollers Based on industrial use, rubber rollers manufacturer design and fabricate rubber rollers. There types comprise: Ink Rollers: These are the rollers being used to apply ink to paper and a host of other materials. Rollers may have a sophisticated cavity for ink or may be designed to apply ink. Laminating rollers: These are fabricated using heat resistant materials, including silicon rubber. These are used to laminate materials on a wide scale, heated up to 500°F before application. Drive rollers: Such rollers rely on movement and are used in a wide range of industries for web and converters machines. This function with the support of integral shafts embedded with a keyway that acts as a gear. Guide rollers: These rollers are also called idler rollers as they give support to various other systems of rollers, including conveyors. What’s particular about these rollers is that they do not move anything. Grooved rollers: These are called so because these are embedded with a grooved pattern. These are generally applied to moving systems, including belt-driven conveyor systems. Conveyor rolls: These types of rubber rollers are used to move or convey materials from one production line to another. Live shaft rollers: Such rollers are manufactured to endure challenging environments and high load quantities. These are equipped with external bearings wherein not only the roller shaft but also the roller rotates. Dead shaft rollers: These are embedded with internal bearings which are situated at the same place as a spinning roller. This spinning roller revolves around a stationary shaft. Cleaning rollers: As the name suggest, these kinds of rollers are used for a cleaning purpose, to remove dust and dirt particles from various types of surfaces. Spreader rollers: Such types of rollers are applicable for webs spreading machinery and a host of other spreading applications. Their application stretches and spreads the web and prevents wrinkles. Stinger rollers: These are manufactured and configured like dead shaft rollers. Owing to their applications, these are being leveraged for a wide range of marine applications. Urethane rollers: Such rollers are also known as polyurethane rollers as these are manufactured using synthetic roller from polyurethane. These types of rubber rollers are used in various applications, including data storage, packaging and assembling, printing, material handling, measurement systems and office equipment among others. Advantages of rubber rollers Rubber rollers are being used cutting across industries for a wide range of applications. These provide numerous advantages. In comparison to metal rollers which are being used in different types of conveyor systems and industries, rubber rollers have high coefficient of friction. This property offers magnificent grip in various moving parts and components. Besides, rubber roller doesn’t lose shape after being compressed during application processes. It achieves normal shape at the earliest. It isn’t over yet. Rubber is a fine absorber of shocks and resists wear and tear. There’s another advantage, after continuous use rubber gets damaged, unlike other materials, it’s easy to replace, overhaul and repair. As an industrialist, what else do you expect from a roller! Industry Rubber rollers are being used in numerous industries for a wide range of applications. These are predominantly used in conveyor belts during the production process to move finished or under process goods. It’s because of its key property – high coefficient of friction. Rubber rollers are being used in a number of industries, including: Summary Rubber Rollers are a boon to the industrial movement. Industries globally are employing them to streamline their production process and scale their business. Quality makes all the difference in production. While buying rubber rollers, including rubber bow roller from an India-based manufacturer, make sure these are in line with the global standards. After all, it’s going to impact the future of the company! Never settle for low quality.

What are flexographic printing sleeves? What are their benefits?

Over the years, the flexographic printing industry has witnessed massive developments. Traditional techniques, tools, and technology have been replaced by contemporary technology. Businesses are keeping abreast of the ever-changing market dynamics. Rightly so! If your business isn’t in line with the market, it wouldn’t sustain itself for long. As a consequence, leading businesses don’t hesitate in investing in innovation and new-age technology. New age technology redefines the Flexographic Printing Digital imaging technology is transforming the flexographic printing sector. Conventional plate making is gradually becoming redundant and obsolete. There’s no exaggeration when we say that modern technology is redefining process technology. The last decades have witnessed major changes in Flexographic Printing enabling it to be compatible with both offset and gravure processes. Digital technology has been a boon for the manufacturer. More or less, the new age technology has reduced variability in flexo printing to a great extent. As far as the current state is concerned, the sector is poised for a sizeable growth in the current financial year – 2021 since clients increasingly demonstrate faith and trust. What’s Flexography? Flexography is being used as a technique to apply designs and colours to a wide range of packaging materials. The packaging material includes paper and plastic containers (including waxed-paper ones), corrugated cardboard boxes, tape, envelopes, and metal foil. It’s a type of rotary printing wherein ink is adhered to different types of surfaces using flexile rubber printing plates. Types of inks being used in Flexography Readers often find themselves in a whirlpool while discussing about types of inks being used in Flexography. Here is the solution; there are different types of inks being used these days, including aniline inks (aniline dyes dissolved in alcohol or some other volatile solvent), polyamide inks, acrylic inks, and water-based inks. Are these inks similar to oil-based printing inks? No, not at all! You would be surprised to know that these inks are far superior to oil-based printing inks. How come? Since they adhere to the surface of the material, whereas oil-based inks are required to be absorbed into the material. Owing to a defined mechanism, inks used in flexography evaporate swiftly, making it safe to be used on wrappers! Implementation of modern technology in flexographic printing sleeves is creating a huge window of opportunities in markets which is conventionally dominated by offset and gravure, including folding cartons and shrink sleeves. Understanding Flexographic Printing Sleeves The sophisticated equipment is employed to mount printing plates on it. Using compressed air, these are floated onto the air mandrel. In a conventional method, the Flexographic Printing Plates are mounted directly on the cylinders. However, since the method isn’t cost-effective, manufacturing companies are swiftly adapting to modern tools. Storage also created challenges. As you know,“Necessity is the mother of invention,” using best-of-breed technology, the Flexographic Printing Sleeves were developed. In industry circles, these sleeves are also known as Plate carriers, Plate sleeves, or Press sleeves. Sleeves are manufactured using different types of materials. These include thermoplastic composites, thermoset composites, and nickel. Depending on requirements, these can be reinforced with fiber. Reinforcement prevents it from cracking and splitting. The reusable reinforced sleeves with foam or cushion are being used for high-quality printing; these are reusable in nature, whereas thin sleeves are developed after one-time use. The former is priced high in comparison to the latter. Unique features Tons of issues and challenges posed by conventional plate mounting have been eliminated using the latest technology-driven Rubber Roller Sleeves. As far as its unique features are concerned, it’s light in weight, durable and simple to use. Besides, working perfectly with less expensive substrates, including tissue, napkins, and paper towels, it’s an ideal material for laydown of solid and metallic inks in packaging applications. Now, an important question emerges, how these sleeves are used? Well, according to industry experts, the sleeves are being utilized in numerous industries in two ways: Industry The sophisticated Flexographic Printing Rubber Rollers are being employed in various industries for numerous applications, including: Custom-built Flexographic Printing Sleeves Custom-built solutions expertise is a privilege of a few in industry circles since it requires a state-of-art facility, vast industry experience, and an astonishing team. Customized to meet the requirements of a particular dimension and size, custom-built solutions are tailored to specific demands. Summary Modern machinery and technology are a blessing in disguise for the Flexographic Printing Sleeves sector. It wouldn’t be an exaggeration to say that the sector has gone for a massive transformation over the years. Conventional methods have been replaced to usher in the new era. It also reflects the foresightedness of industry stalwarts who are setting new benchmarks!

Only a quality steel roller helps companies to scale up their business

The rollers are designed keeping in view their applications in a range of industries. Quality assumes significance here as inferior quality could jeopardize the production process. As a result, companies emphasize the quality of a product. For businesses, it’s important to ensure the quality of the product. A meticulously designed roller is energy-efficient, durable, and reliable. In this write-up, our focus would be to highlight the roller and a pneumatic air shaft. Unique features of steel rollers Here are a few features of a roller: Standard specifications The metallic roller is available in a wide range of specifications. The standard specifications that are most sought after by industries include: Specification The specification may vary from company to company. Few companies also deliver custom-made solutions. What is a custom-made solution? Client’s specific requirements and industry remain at the core of business while working on custom-made solutions. The solution is a bit costly as specific machines and tools are required to manufacture the product. Since it requires the expertise of the highest order and a particular set of machines and tools, only a few hold the competency to deliver a similar solution. A team led by an expert Industrial applications The industry-centric steel roller has found prominence in numerous industries for offering a wide range of applications. Here are a few industries that capitalize on the sturdy roller for scaling their business operation: Besides, there are plenty of other industries that capitalize on this industrial product to seamlessly operate their production lines. Pneumatic Air Shaft Let’s move towards another critical subject of this write-up. The shaft offers quality gripping force. Considering its application, the machine is developed and designed with greater structural strength, at the same time, a powerful expansion mechanism is also ensured. Why this feature? Because such features will help the machine to handle the heaviest roll weights at high web speeds. Prominent features and benefits Before jumping to any conclusion about the machine or if you have made up to procure a pneumatic air shaft for your production line, consider a few salient features: True concentric expansion The true concentric expansion is one of the salient features of the shaft as it minimizes roll bounce and vibration in heavyweight and high-speed applications. Fail-safe operation Since the lugs are mechanically locked, the shaft continues gripping without fail. These features help to maintain fail-safe operations. Independent lug action Each lug set of a pneumatic air shaft gets activated through separate cam springs. This facilitates the core shaft to grip uniformly even when core variations are present. This can even be possible when cores do not cover all lug sets. Positive lug retraction The presence of a sophisticated mechanical system ensures that lugs retract completely. As a result, the shaft never sticks in cores. Spare parts and accessories of the shaft There are a host of sophisticated spare parts that are assembled to form a pneumatic air shaft, these include valve, hose assemblies, protection strip, brass inflator end, inflator chuck, rubber nozzle end, continuous rubber, lug, inflator Chuck, split clamp, inflator Gun and standard inflator stem. Industrial use As there are numerous benefits of the shaft, it has found usage in several industries. These include packaging, textile, paper, plywood, and tyre among others. A few companies also deliver custom-designed solutions.

Why do companies prefer hard-anodized aluminum rollers?

In this business-centric blog, our focus will revolve around the aluminum roller, its salient features and why do companies prefer the roller? But, before we move ahead and take a deep dive into the important subject, its definition assumes significance. What is hard anodizing? Hard anodizing is the term identified to express the functional refinement of aluminum components in the form of the anode. Scientifically, the process is also defined as hard coat anodizing. Under the process, a very thin, non-metallic conversion coating gets created over the base metal. Base material and its parts become fully integrated with the coating. As a result, high bonding of the anodic layer gets developed. Impact and effect of the new age roller To enhance production, manufacturing companies across India are emphasizing using the excellence-driven hard-anodized aluminum roller. The roller helps in enhancing the production line. Why do companies give preference to industrial rolls made of aluminum? There are sufficient reasons to prefer metal over other metals. According to industry experts, the anodized roller is chemically stable. At the same time, since the anodizing process is a reinforcement of a naturally occurring oxide process, it the roller is non-hazardous and produces no harmful or dangerous by-products. Prominent features and advantages Before deciding on your business, you should get aware of the impact the roller brings along with it when deployed at the manufacturing site. Over the years, hard-anodized aluminum roller manufacturing in India has witnessed a positive growth. The reasons are obvious. There are a few features that make the roller stand out from the crowd. In this space, we are sharing a few advantages that will expand your knowledge about the critical roller. Durability The majority of parts of the metal show no wear or tear during installation. As a result, the roller depicts tremendous durability. Maintenance The hard-anodized aluminum roller requires the least maintenance. Money saved is money earned! Businesses the world over prefer products that require the least maintenance. Due to continuous use, the roller may appear shabby with dust and oily particles all over it. You will be shocked to learn that cleaning with liquid with detergent will restore the roller to its original look and appearance. Cost-effective It has been proved that anodizing is cost-effective, so are rollers. The least maintenance validates the fact. In addition, since it depicts high durability, it minimizes replacement cost. Environment-friendly Anodizing process is an environment-friendly industrial process as it results in the least residues, at the same time. It’s not harmful to human life. Corrosion-resistant Under the anodizing process, a thicker oxidized surface gets created over the base metal. As a consequence, the roller demonstrates high corrosion resistance and the least wear and tear. In recent years, the emergence of technology and innovation has led to numerous industry-centric changes. Companies that are engaged in hard-anodized aluminum roller manufacturing in India aren’t lagging. Using modern tools and technology, companies are manufacturing business-tailored anodized aluminum rollers. Why Arvind! Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, hard-anodized aluminum roller, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, lug type air shaft, and core saver/core restorer among others.

Choose Industrial Rubber Roller Manufacturer Wisely

A wide range of industries across the globe are drawing benefits from industrial rubber rollers as the cylindrical product plays a significant role in manufacturing a variety of products. Rubber roller manufacturing has witnessed sweeping changes, driven by the continued evolution of technology and engineering. The availability of high-end technology is empowering industrial rubber roller manufacturers. What is a Rubber Roller? A manufacturing industry-centric rubber roller is a cylindrical-shaped product wherein metal remains at the nucleus. By using the latest machines and technology, a coating of rubber is applied to the product. Rubber coating, types of rubber coating, length, diameter, etc. depend on the industry and application. In this regard, you can connect with a famous industrial rubber roller manufacturer. Choose the Manufacturer Wisely Better the quality of the product, the better the production. That’s why it makes sense to buy a quality-driven product. In this age of tough competition, quality has assumed significance. Rightly so. Whether it’s the end-user or a vendor, everyone is looking for quality products. Quality Factors to be Considered When choosing a rubber roller for your manufacturing company, carry out due diligence exercise. Some of the pivotal factors, you can consider when choosing the manufacturing industry-centric rubber roller are: In addition, what you can do is – you can also explore the website of the industrial rubber roller manufacturer. A meticulous examination of the website can give you an idea about the company, its standing in the market, clientele, etc. Don’t jump to conclusions, unless you have strong facts to support. Quality matters. No compromise on it!

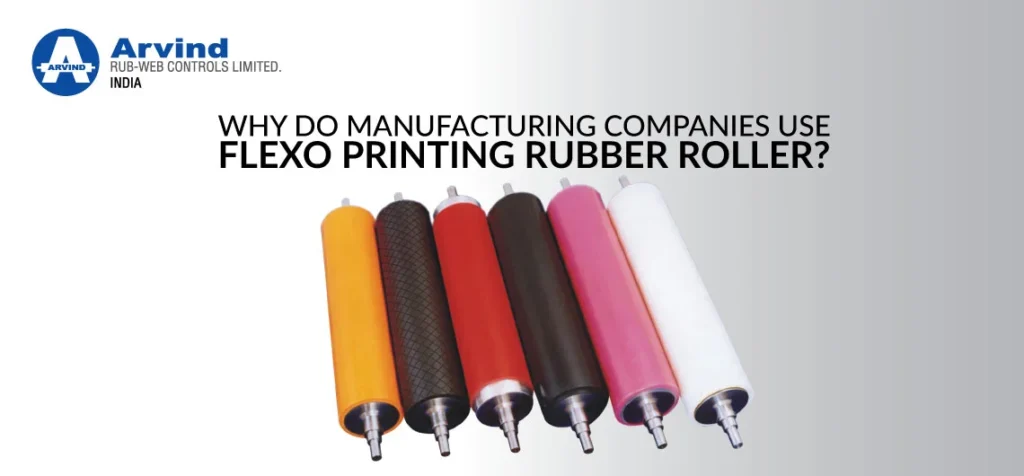

Why do manufacturing companies use Flexo printing rubber roller?

Those who are working in manufacturing industries, like packaging, paper, plywood, and tyre among others are aware of the importance of flexo printing rubber roller. In this concise blog, we are making efforts to share with you the intricacies related to the important machine of the manufacturing industry. However, before we move forward, the importance of rollers assumes significance. Because, for unawares, it’s a new term. Therefore, let’s understand business-centric rubber rollers. Why do companies use industrial rubber rollers? The rollers have found usage in many manufacturing processes across the globe, including our own India. These play important role in different types of manufacturing processes of industries, such as textile, film, sheet, paper, tyre, packaging, and printing. The industrial rubber rollers have found usage in the application that requires a high degree of contact and holding friction. In addition, in material processing applications that demand soft touch. It appears the picture is crystal clear now. Let’s now move towards the key subject, the flexo printing rubber roller. Learning about flexographic printing rubber roller As the name suggests, these types of rollers are integral to flexography and have found usage in flexographic printing. Despite the innovation and technological development, rollers can’t be imagined without rubber. Rubber continues to occupy center stage in the flexographic printing industry. According to industry experts, rubber coverings are applicable in numerous flexo areas, such as laser engraved plates, laser engraved cylinders, and fountain rollers. The rubber compound is the key here as numerous functions depend on its physical and chemical properties. Every rubber covering is unique in the sense that it has suitability for specific applications. Application of the roller and flexo printing The roller has been designed for flexo printing on different types of packaging. For unawares, flexo printing is a printing process wherein printing application is implemented with flexible print forms. These print forms are also known as printing plates. As the basic raw material is concerned, it’s photopolymers. Why do companies prefer flexo printing? Do you have any idea? This is one of the most popular and reliable printing processes in the packaging sector. Mid-size to MNCs and business conglomerates prefer flexo printing. It creates the finest print quality on a wide range of printing substrates Salient features of the roller The industry-centric roller has been identified with many salient features. These include: Custom solutions A few manufacturing companies in India hold the expertise to manufacture custom solutions as state-of-the-art infrastructure is a must. Furthermore, a team of expert engineers and technicians is also necessary to meet the specific demands of customers. If you are looking for a custom solution for your manufacturing unit, make sure you connect with a company holding professional experience in custom solutions. Conclusion Rely only on leading brands. Quality matters in this era of cutthroat competition. In this era of technology, you have plenty of options to find the perfect roller manufacturing company for your manufacturing process. The solution is just a click away from your laptop/ mobile. Browse a few web portals. Afterward, get in touch with a leading company with credibility and industry experience. Let’s collaborate… Explore Arvind Rub-Web Controls Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Our quality-focused, industry-centric product range includes flexo printing rubber roller,industrial rubber/ebonite/metal rollers, hard-anodized aluminum roller, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, lug type air shaft, and core saver/core restorer among others.

What is a bowed roller and its benefits and advantages?

In this short industrial blog, we are going to focus on the significance of hollow roller, its benefits and a host of other important subjects. Before moving forward, it’s important to learn basics about the roller. It will help unware to grasp the subject better. For those working in manufacturing, this isn’t a surprise as most of them are well aware about the product. So, what is this product? Why it has so much importance in manufacturing? Learning about the roller The manufacturing industry specific roller is also popular as banana roller, bowed web spreading roller, variable bow expander, and curve expander among others. Since the roller has been identified with a few shapes, it draws its name from there. It looks like a bow, therefore became popular as a bow roller, many identify it with banana, hence people started calling it banana roller. There’s a reason behind every name. Salient features Specifications The industry centric roller is available in various specifications: Applications It has been in use in a number of industries, including textile. As far as its application is concerned, it’s an integral part for spreading web material uniformly. It helps to avoid interweaving of material. In addition to remove wrinkles and creases. The roller has been a game changer for manufacturing companies as it helps in a wide range of applications. According to roller industry experts, it’s main applications include: Industries drawing benefits Since the roller has numerous salient features that help it to conduct various types of applications with ease, it has found usage in many manufacturing industries. These include: Is there any option for custom solutions? Besides standard dimensions, a few companies have developed expertise to provide custom solutions for bowed roller, hollow roller. Do you have any knowledge about custom solutions? For unawares, a custom solution provides solution to companies according to their clients’ industrial requirements. Dimensional requirements and industry features remains at the core while delivering custom solution. Choose an ideal partner Yes, that’s right. Don’t be in a hurry while choosing a partner for your business. An ideal product will take your company to the next level, whereas an inferior quality could rob your production line. That’s why focus on quality and credibility of the manufacturers and suppliers. In this era of technology finding a perfect company isn’t a big challenge. Simply go on leading search engine Google. Enter a few common key words, like bowed roller. Search engine will come up with search result. Access the initial few links/ website. Speak with their customer care and sales team to learn about the various features of the product. Unless the product meets the requirement of your business, don’t take the final decision. End your search for bowed roller at Arvind Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, hard-anodized aluminum roller, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, lug type air shaft, and core saver/core restorer among others.

Modern printing rubber rollers are increasing production

Companies cutting across domains are emphasizing the use of printing rubber rollers of premium quality since similar features enhance production, at the same time cutting down production costs. In this short, yet important blog, we are going to highlight a few important subjects that hold importance for rubber roller manufacturers, suppliers, and industry users. Before we make deep dive into the subject, it’s important to learn about the basics of rubber rollers. What is a rubber roller? A wide range of industries across the globe carries out numerous applications using a rubber roller. So, what is a rubber roller? According to industry experts, a rubber roller is a round shaft that is made of steel, aluminum, carbon, or a host of other composite materials. This metallic shaft has an elastic covering. The industrial rollers are of numerous types, depend largely on applications and industry. Learning about printing rubber roller As the name suggests, the printing rubber roller is custom-made for the printing industry. The sophisticated rollers are speedily changing the dynamics of the printing industry. Ruthless market competition is also strengthening the industry as printing rubber roller manufacturers are combining innovation with technology. Such things are good for the industry as competition leads to excellence in quality. Using flawless CNC lathe machines, premium quality raw material and professional expertise of engineers and technicians, printing rubber roller manufacturers produce an excellent quality product. A covering of specially formulated rubber further enhances the quality and durability of the product. Unique features A premium quality roller has numerous distinct features. These features set it apart from the crowd, including: While placing your order, don’t forget to ensure features of the product you are procuring Applications The industry-centric rollers have found usage in various applications, including: Modern printing rubber rollers are competent enough These have been designed and manufactured keeping in view the dynamics and specifications of leading printing machines that are in use in industry, including: Custom printing rubber roller The printing rubber roller manufacturing in India is witnessing positive growth, riding on rising socio-economic activities. A few companies in India hold professional expertise to provide custom-made industrial printing rubber rollers. These are in line with the industry-specific requirements and specifications, including diameter, thickness, and length. If you are looking for a custom-designed roller, start exploring the expertise of popular and leading companies. As quality impacts production, never settle for low quality. End your search for an excellence-driven printing rubber roller with Arvind Rub-Web Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the centre of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

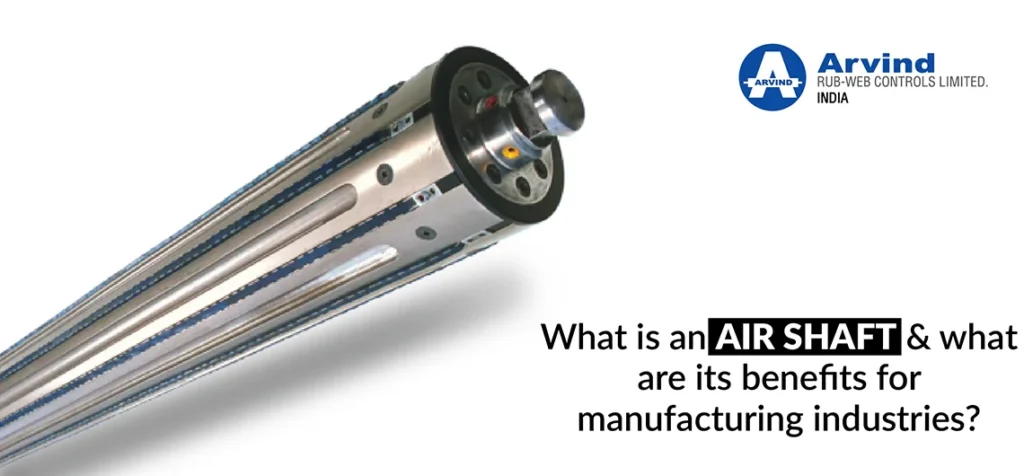

What is an air shaft and what are its benefits for manufacturing industries?

Innovation in technology and engineering are swiftly changing the dynamics of manufacturing industries. Traditional processes and machinery are no longer effective. Emerging technologies are further pushing the growth of the industry. Overall, the future of manufacturing looks brighter in India. Over the years, taking advantage of innovative technology, companies have launched numerous innovative engineering products. It’s also an opportunity for manufacturing companies to redefine and reinvent their manufacturing processes, keeping in line with the market demands. In this blog, our focus will be on industrial air shafts and their benefits for manufacturing companies. Before we move forward, let’s learn about industrial products. Learning about the product Air shaft is also known in the industry circles by various other names, such as air expandable shaft and air expanding shaft. It has found usage in numerous industries for a wide range of applications. The industrial product is utilized in various manufacturing processes for fitting into the core. This core wounds different materials, including paper, cards, plastic fil, etc. The manufacturing industry-specific machine has been designed to readily expand on fitting into a core. Indian air shaft manufacturers are using the latest machinery and technology to manufacture a world-class product, enabling companies to manage various manufacturing processes without any challenge. Unique features The industry-centric product demonstrates numerous unique features when applied during different manufacturing processes, including: Besides, the shaft has the efficiency to grip the core, without causing any damage, at the same time offering a positive interface to control the web via motors & brakes. Physical features As an important decision-maker of a manufacturing company, ensure that the air shaft you are about to deploy at your manufacturing process is in line with the above-mentioned unique and physical features. Buy the product from the reliable Due to the flourishing manufacturing ecosystem in India, the demand for air expandable shafts has been rising. There is no dearth of air shaft manufacturers in Ahmedabad, however, finding a trusted partner remains a challenge. Using the latest technology, you can ensure quality. Google the keyword air shaft manufacturers in Ahmedabad, the search result will come up with a few suggestions. Access those links. Read their website carefully. If you have any queries, speak directly with their customer care. Unless you are satisfied with the quality standards, don’t place your order. Industries using air expandable shaft There are numerous industries that use this product. A few major industries include: Are you looking for a custom-made range of air shafts? A few manufacturing companies require custom-made solutions. Their manufacturing process doesn’t suit standard designs ad specifications. For similar companies, there are a few air shaft manufacturers that have the expertise to develop custom-made solutions. You can connect with these experts and discuss your requirements. Arvind Rub-Web Controls Ltd. with four decades of pioneering experience in their armoury, provide custom-made airshafts. End your search for an excellence-driven printing rubber roller with Arvind Rub-Web Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the centre of our corporate strategy. Starting with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries! Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

Industrial hard chrome plating roller optimizes production

Materials Plated Using the latest machines, tools and technologies, roller manufacturing companies are developing hard chrome plating rollers for various manufacturing industries. The hard chrome roll plating has been found effective on a wide range of materials. Depending on your industry requirement, you can choose the base metal. These include: Important features of the roller The industrial roller has been well received by industries as it has brilliant qualities, enabling it to display optimized performance. Here are some of the main features of the hard chrome plating roller: In addition, the industrial hard chrome plating roller is durable. Therefore, it is worth investing in the roller, if you are managing an industry or holding a decision maker position with a company. Industries using the roller Ultrasonic testing, flawless trunnion design, and galvanization to name a few make the Hard Chrome Plating Roller a classic example of engineering marvel. Packaging industry world over trust and rely on the product to conduct a broad range of applications seamlessly.