How To Choose The Ideal Quick Change Sleeves (Rubber Sleeve)?

Quick Change Sleeves are changing the fortune of a variety of manufacturing companies. In this blog, we are going to highlight a few factors that you must consider before choosing the product for your manufacturing unit. Unique Features of the product (Quick Change Sleeves) This is an important section of this blog. As an owner of a manufacturing company wherein rubber roller sleeves are being used, like a Packaging unit, you require a quality-driven range. if possible, your production output will drastically suffer. that’s why, it makes sense to share the unique features of the product. A quality-driven product is identified with a set of unique features. What are they? How would you ensure the quality of the sleeves, you are all set to buy? These with some similar questions are automatically solved when you have a product that displays the following unique features: Specifications It’s now time to share the specifications of the product. As far as dimensions are concerned, it varies from rubber roller manufacturer to rubber roller sleeves manufacturer. That’s why, choose the specifications that absolutely meets your requirement. Here, we are sharing the specifications of rubber roller sleeves by Arvind Rub-Web Controls Ltd., a prominent manufacturer, supplier, and exporter of industrial rubber rollers Quality is brand identity In this era of tough competition, don’t settle for less. Never compromise the quality of the product. Remember that quality doesn’t come cheap and never expect quality from a company that uses regressive machinery. When you choose the product for your factory, validate the quality parameters in place at the manufacturing facility of the rubber roller sleeves manufacturer. How to ensure the quality of the product? The quality product adds value to your production unit and helps the company roll out quality-driven products. Validate the quality policy in place at the manufacturing unit to ensure the quality of the product. Customization Customization is a professional competency gained over a period of time. Only a few manufacturing rubber roller manufacturer holds the expertise to deliver customization. If your manufacturing unit requires a specific kind of rubber roller sleeves, you may be expected to connect with a prominent rubber roller manufacturer who holds expertise in offering custom-made products. Don’t forget that custom-designed product is a rarity. Only a few companies have that rare potential. Discuss your requirements with the manufacturer, and ensure that the company has the required infrastructure to deliver customization. Application of the rubber roller sleeves The quality-driven range is designed to meet a variety of industrial applications, including Roto Gravure Printing, Solventless lamination, Solvent-based lamination, Flexo graphic printing, Adhesive coating, and ESA printing among others. In this regard, you can connect with a leading rubber roller manufacturer in Ahmedabad. Industry From the application section, let’s now shift our focus to the industry part. Numerous industries are drawing benefits from the robust rubber roller sleeves, including Packaging. Conclusion Quality should always remain at the core of your business. No negotiations on this. Only choose the quality-driven quick change sleeves for your manufacturing unit.

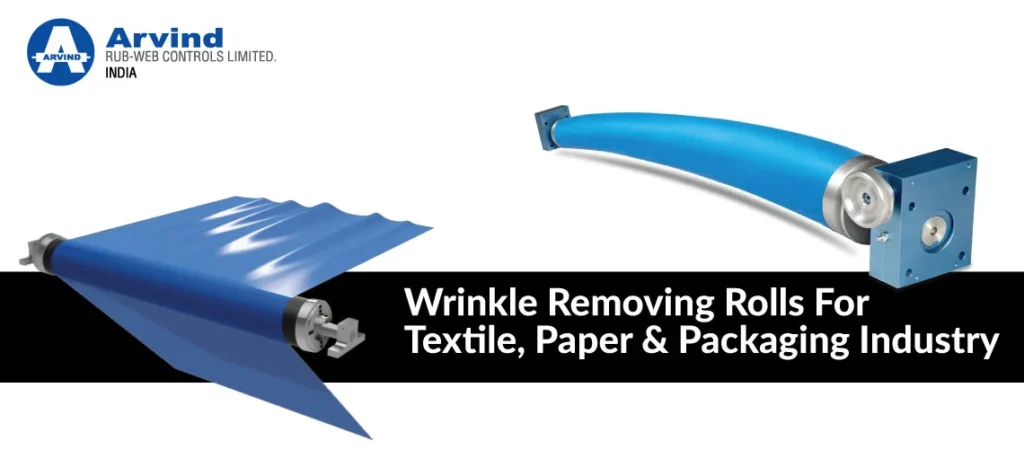

Wrinkle Removing Rolls For Textile, Paper And Packaging Industry

Arvind rubber is the most prominent and experienced manufacturer, supplier and exporter of Rubber expander roller. We have an experience of more than 30 years and are serving internationally with our high-class products. We deal in all type of bow rollers that are designed in a customized way to suit various types of industry-specific requirements. Spreader rollers: Rubber spreader rollers offered by us provide support in performing many industry oriented functions. These bow spreader rollers support efficient removal of wrinkles from Textile Processing machines such as Bleaching machines, Calendars, Dyeing and Drying Ranges. These bow rollers consist of many unbelievable features that make it suitable for industry works. These rollers are abrasion resistance, chemical resistance, and high-temperature resistance. The products we supply are used for laminating paper, foil, and films by the packaging industry. We are the leading supplier and exporter of bow rollers for the packaging processes and are serving customers not only on a national level but on an international level as well. Features: Rubber expander roller possesses many amazing features that make it a must-have tool of the packaging industry. The spreader roller comes with a Scratch resistance and low maintenance features. It does not only help to remove wrinkles but facilitate workers by separating slit and eliminating baggy centre. These spreader rollers also control slack edges and have a long service life. Though there are many manufacturers in the market but spread rollers manufactured by Arvind rubbers go through many quality parameters before delivering to the client. Our customized range of spread rollers are made with superior quality material and technique. Why we? Arvind rubbers are the primary manufacturer, supplier and exporter of Bowed Rubber Rollers in the market. These rollers are known by numerous names but banana rollers, wrinkle remover rollers are the most common name for these. They are used to reduce slack ends, wrinkles, spreading and slit separation. Our qualified and experienced team tests make sure that our spreaders fulfil the requirement of industrial standards and norms. Our rubber expander roller offers superior performance and unmatched quality. Despite this they are Abrasion resistance, tear resistance and resistance against ozone and aging. Available in the wide range they are suitable for many industrial works and are the most important tools. We believe in satisfying our customers to make this relationship a long term bond. Inquire us for your need of Spreader roller, Rubber Expander roller, Bow Expander Roller.

Air Expandable Shaft An Amazing Tool For Slitter Re-Winder Machine

Air Expandable Shaft Air expanding shafts is an advanced winding shaft that is used for slitter re-winders. Manufactured by using high-quality raw material and techniques these shafts are a prominent tool of the packaging industry, steel industry, and paper industry. Arvind rubbers are the leading manufacturer, supplier, and exporter of these shafts in the national and international market. Features of Air Expandable shaft : Our air expandable shaft offers many extraordinary features that make them stand apart in the industry. These additional features are added to help in the comfortable working of the tool. We understand the importance of tools in industrial operations thus we are engaged in catering to you with high-class products: Capabilities: Air expandable shafts play a very important role in paper and packaging industries. The incredible features and outstanding capabilities make it a must-have tool in many industries. This shaft consists of many supportive features such as a slotted shaft, rubber bladders, hard and ground steel cage with ball type gripper that makes it one of the outstanding tools. Why us? Arvind Rubber is engaged in manufacturing a comprehensive range of Air Expandable Shaft for the packaging industry, Steel industry, and paper industry.Air expanding shafts manufactured by us delivers the best service in the industry.Our air expanding shaft serves our customers with superior performance for winding application in the widest range of roll handling processes. Our winding products are capable of adjusting to the varied condition of industry functions such as speed variations and core width variations.We are here to help you with a high-quality and budget-friendly range of products that let you concentrate on your work rather than struggling with tools.

An Overview Of Air Shaft, Air chucks And Its Types- Brief Info

In the industrial world of winding and unwinding materials such as paper, plastic films, foils, and textiles, air shafts and air chucks play a vital role. These mechanical tools are indispensable for achieving efficiency, accuracy, and smooth handling during reel operations. This blog aims to provide a comprehensive overview of air shafts, air chucks, their applications, and types, with a focus on high-quality solutions offered by Arvind Rubber, a trusted name in the industry. What is an Air Shaft? An Air Shaft, also known as an air mandrel or air expanding shaft, is a device used to hold the core of a roll in place during winding or unwinding operations. It is designed to expand and contract through the use of compressed air, allowing for a quick and firm grip of the core without causing any damage. When inflated, the air shaft expands using lugs, strips, or leaves to tightly grip the core and ensure smooth rotation. When deflated, it contracts, allowing easy removal of the roll. Air shafts are widely used in paper, packaging, plastic film, textile, and converting industries where high precision and operational speed are essential. Advantages of Using Air Shafts The use of air shafts brings several operational benefits: Types of Air Shafts There are different types of air shafts designed to meet diverse industrial needs. Let’s explore the most common ones: 1. Lug Type Air Shaft This is the most popular and versatile type. It uses steel or rubber lugs that expand radially to grip the core when air is injected into a central bladder. These shafts are ideal for heavy-duty applications and are available in various materials such as aluminium, steel, or carbon fiber. Sizes typically range from 11mm to 300mm. 2. Leaf Type Air Shaft Leaf-type shafts are used for sensitive applications where minimal core distortion is essential. They offer 360° contact grip, ensuring uniform expansion. The “leaves” are flexible yet strong, making them perfect for thin-wall cores or high-speed operations where concentricity matters. 3. Strip Type Air Shaft This type features external air bladders and metal strips or bars that provide high strength with a lighter weight. Their high strength-to-weight ratio offers performance benefits in operations requiring quick movement or reduced shaft mass. Applications of Air Shafts Air shafts are used across multiple industries and in various reel-handling operations. Common applications include: What is an Air Chuck? An Air Chuck is a mechanical gripping device used primarily in winding/unwinding applications or machines where the shaft needs to be held securely. Similar in function to air shafts, air chucks provide powerful core holding by expanding when air is supplied. They are often used in turret winders, slitter rewinders, and printing machines where high torque transmission and quick core changes are essential. Air chucks are available in: They offer efficient locking mechanisms, minimal vibration, and reliable performance even in high-speed operations. Why Choose Arvind Rubber for Air Shafts and Air Chucks? With decades of experience in manufacturing high-performance industrial components, Arvind Rubber has become one of India’s leading suppliers of air shafts, air chucks, and rubber rollers. Here’s what sets Arvind Rubber apart: Whether you’re operating at high speeds or dealing with variable core sizes and materials, Arvind Rubber’s solutions are built to handle it all efficiently and cost-effectively. Conclusion Understanding the function and types of air shafts and air chucks is essential for anyone involved in web handling, converting, or packaging industries. These tools provide the foundation for efficient winding and unwinding operations, ensuring that production lines run smoothly and without interruption. By choosing high-quality components like those from Arvind Rubber, businesses can enhance their production capability, reduce maintenance costs, and ensure greater reliability in daily operations. If you’re looking for durable and high-performance air shafts or chucks for your industrial setup, Arvind Rubber offers an extensive range of customizable, budget-friendly, and industry-tested products.

How Industrial Rubber Roller Manufacturing Process Works

Assembling of Rubber Roller requires innovation and experience. We centre around components, for example, the exhibition of the rubber mixes, completing exactness, quality support, roller centre material and structure, and appropriate holding of rubber and centre. Every one of these parts is imperative to consider a quality item toward the end. Rubber Nip Roller has a streamlined presentation when they are fittingly chosen for every application thinking about all the important conditions. Rubber Roller Manufacturing Process Rubber Fabrication Standard rubber roller production includes a rubber manufacture step, which can be accomplished either by handling strategy, expulsion, projecting, or bite the dust press. Plying involves the calendering cycle, during which, to make calendered rubber sheeting, rubber is gone through a mix of rollers. As the rubber sheet travels through the rollers, it is smoothed and leveled. Utilizing this cycle, two kinds of the polymer can be sandwiched together if an application requests. When the calendared sheet is prepared, the sheet turns into rubber in front of an iron centre or another metal centre. With that, it is a rubber roller. Given customer prerequisites, sheets can be cleaned, coated or emblazoned. Extrusion is the most widely recognized assembling technique that includes an extruder. With this strategy, a rubber profile of fixed cross-sectional can be made consistently by-going rubber through a bite the dust. In this cycle, crude material is warmed by going it through a screw system, which warms material by a consolidated activity of pressing factor and temperature, and afterwards, the material is pushed through the kick the bucket. The basic advance in this manufacturing procedure is restoring, which includes moulding the rubber item in a controlled climate where it is uncovered foreordained temperature and pressing factor. The relieving cycle invigorates the underlying rubber item by eliminating porosity. Roller Manufacturing At Industrial Roller Company, Rubber rollers are normally fabricated through projecting or trim, yet they may likewise make through expulsion. Projecting processes are used uniquely with rubber rollers that have metallic centres. For this situation, centres are shaped through a metal projecting cycle like stepping, after which they are bound to a rubber covering. Restricting is done utilizing a holding specialist that normally made of polymer-dissolvable arrangements, a preliminary coat dependent on phenolic-style saps and a top layer of blended polymers and other different materials. Rubber roller moulding processes incorporate pressure trim and infusion shaping; these are utilized for strong rollers. Extrusion of rubber rollers happens when producers heat picked elastomeric material(s) and press the liquid material through a bite the dust that has a pin in the middle to manufacture the empty cylinder Scoring The following stage includes surface scoring. Various scores can be made on a surface of rubber, including square, trapezoidal, “V”, twofold edge saw, half hover, and round. Also, on a rubber roll, these depressions can be made vertically, evenly, helically, worm, jewel cut score and screw strung. Review Toward the finish of this progression, the items are reviewed for abnormality. Materials The elastomeric materials from which Manufacturers, India can browse is genuinely changed. Every material has its own qualities and shortcomings, however, every one of them has some degree of protection from water, wear, certain synthetic compounds and warmth boundaries. Among the many, a couple of materials that are oftentimes used to manufacture rubber rollers include EPDM, silicone, nitrile, neoprene, polyurethane and normal rubber. Metal centre rollers are typically made with steel, tempered steel, aluminium or another metal that fits application prerequisites. Contemplations and Customization When planning a rubber move for a particular application, producers think about various components, for example, synthetic contact, standard prerequisites, required length, load limit, thickness, shape and tightening, and so forth They likewise consider roller speed. On the off chance that a roller is presented to high velocities with enormous burdens, producers, for the most part, suggest you purchase rubber moves with a centre that can be water-cooled. At the point when rubber is nipped, it discharges heat—called hysteresis warmth—and water cooling is a compelling method to contain that heat. Producers can undoubtedly redo rubber rolls per your details. For instance, you may arrange rubber moves to meet remarkable width and length details, and you may arrange them in an assortment of thicknesses and shadings. Moreover, makers can utilize various sorts of rubber to make rollers idle against synthetic substances dependent on an application. They can likewise put on forte completes or coatings and claim to fame moulding. Discover more by examining customization with your forthcoming provider.

Transforms business using the efficient and industry-specific rollers

The ever-changing market dynamics makes it important to stay abreast and streamline product and services in line with the requirement of the market. Otherwise, the business will lag behind the competitors. Industrial rollers are essential in a wide range of industries, including textile, tyre, plastic, packaging, paper, plywood and laminate, and steel among others. The roller manufacturing industry in India is soaring high. There are strong reasons to corroborate the fact. The positive economic landscape is the major factor. There are companies galore in the market offering a wide range of rollers. Before placing your order for rollers to fulfill the demand of your business, perform an extensive evaluation of the company and products. Range of rollers A gamut of rollers is available in the market. Depending on the industry requirement and specifications, businesses can employ the roller. Here is the concise introduction of a few industrial rollers, playing a significant role in enabling businesses to accomplish their business goals: Rubber Rollers Industrial rubber rollers as the name indicate aren’t general rubber rollers. These are industry-specific rollers designed and manufactured to conduct the designated processes in a wide range of industries. Keeping in light the demand of the industries, these rollers are available in different types of shape, size, and specifications. Basis, the particular demand of the industry, businesses can install and utilize the rollers. Range Rubber rollers range include: Industry application Rubber rollers are being used in a gamut of industries. Paper, pulp, and petrochemicals to name a few utilize the advantages of the rubber rollers. Here are some of the applications: Custom-made In layman’s language, custom-made rollers are designed and manufactured to cater to the need of a specific industry. The team of the particular industry collaborates with the production and design engineers of the manufacturing company. Specifications are examined and evaluated to produce the custom-made roller. Features of industrial rubber rollers The rollers, which deliver excellent performance, are identified with a set of prominent features, including: Use the appropriate roller Experts suggest rollers tailor-made for a specific industry optimizes performance, while faulty or erroneous roller could be disastrous. Former increases your business, while latter adds on to the production cost. None of the companies would imagine being in a disastrous situation. The Thumb rule of the business is progress. Nip rollers Nip roller is another significant industrial roller. These are an integral part of the web process. It comprises a combination of rollers; one is hard, while the other one is soft and elastic. These are designed and developed to work in unison. Commonly opened and pressed together. This mechanism is performed by one or more than one air cylinder. While the pressure is monitored and controlled externally. Industry application Nip rollers have found usage in a range of applications. These are widely utilized in textile and a host of other industries. Their application includes: Salient features of industrial nip rollers The industry-specific rollers are equipped with various salient features. These include: Install and use appropriate nip roller Never compromise with the quality. Only install and use a nip roller suitable to the business. Erroneous is bound to impact the business. Why Arvind Rub-Web? With more than four decades of unparalleled industry experience in its quiver, the Arvind Rub-Web Controls Limited has established itself as the numero-uno leader in the industrial rubber rollers’ domain. Backed by the enormous domain expertise and brilliant hands-on experience of a cohesive team, the Ahmedabad, Gujarat nestled company has been enabling businesses from diverse domains in accomplishing their business goals. The long list of clientele spread in more than 52 countries demonstrate our leadership in the domain. If you are an owner or decision-maker of the business and scouting for rubber, nip, and industrial rollers manufacturers in India, then end your search with Arvind Rub-Web. Their product portfolio comprises industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others. Industry expertise enables the company to manufacture custom rollers. Conclusion Industrial rollers are the backbone of businesses. They play a pivotal role in defining the business. Installation and use of the appropriate roller augment performance. Always use the tailor-made rollers designed and manufactured to suit the specific requirement. Rollers are manufactured adhering to specific industry standards. Quality matters. Never negotiate with the quality. A lackadaisical approach could prove futile!

Reasons How Rubber Rollers Makes Life Easy For Industries

Rubber Rollers The rubber roller is one of the most important parts of the manufacturing and processing industry. It’s mainly used in the Textile, steel, paper, and packaging industry. These rollers are crafted according to the industry requirements and offer optimal performance. There are many different kinds of rollers, built according to the requirement of the industry. Rollers for various industrial use Silicone rubber rollers Silicone Rubber rollers come in many different colors & sizes with required hardness (25 to 85 shore) along with surface grinding and suitable Bearing size. It is made up of ultimate quality silicon raw material. This material has an extremely high-temperature range and it is the best electrical insulator too. The silicon rubber roller has a heating base in it. Silicon Rubber Rollers are used for many different applications. It is used for cutting the sealing, hot melt coating, extrusion coating, foil processing, holography, poly coating, heat & press lamination, and thermal lamination to name a few. Groove rollers The Groove rollers are manufactured at a very economical price for industry use. These rollers are made by using ultra-modern machinery & ultimate quality raw material that is available in different lengths and diameters. These rollers are known for their effective working & accurate finishing. It has various properties like longer stability, corrosion & moisture resistance. There are many different types of grooves available according to their use like vertical groove, helical groove, screw cut groove, horizontal groove, double-helical groove, diamond cut groove, and all types of grooves. And these grooves are used for sealing machines, pouch machines, and remove all types of wrinkles & slips. Ebonite Roller Ebonite roller is manufactured of supreme quality that is designed and fabricated with the use of the latest tools and advanced technology. It is capable of surviving the high temperature of steam and water. That’s why it provides excellent performance and long service life. These rollers are available in various sizes. Ebonite rollers are very easy to install, has precise dimension, long service life with high functionality. Nips Rubber rollers Rubber roller made of the different compound as per their use and working environment. Nip Rollers are high-quality rubber rollers, used for the Textile industry. These are used under different working conditions for better Squeezing efficiency. These rollers are chemical resistant, have stable strength and uniform hardness which protects the roller core and shaft. It is used for varied processes like Singeing, DE sizing, Impregnating, Bleaching (PTR), Mercerize Range, Stenter m/c, Washing, and Dyeing, etc. for the textile industry. Teflon roller These rollers are Teflon coated, are widely used in the textile industry. The Teflon rollers prevent corrosion and use for non-stick applications. The Teflon coated surface of the rollers provides great resistance against general wear & tear and heat. Teflon roller manufacturers in India export an extremely wide range of industrial rollers, which are designed according to advanced industrial standards. Customization can be done to meet specific dimensions. Guide rollers These rollers are installed for direction control of the unit loads. The application of the guide roller is to maintain the guided direction of a moving object like a drawer, door, fence, or tank track. This roller provides easy movement of the objects with less resistance. Guide Rollers allows easy lifting of the object without causing any damage. Printing rollers The Printing rollers are assembled with three different rollers. First is the ink ductor roller that first receives the ink. The second is the ink form rollers that give the ink to the printing plate and the third is distributor rollers through which paper comes back after printing. It is used for paper printing or press purposes. Lamination Rollers Lamination rollers are used for laminating important stuff like important documents.This roller includes hard chrome plated surface & Rubber roller. lamination rollers mechanism is to apply a thin plastic cover to paper documents with the combination of heat and pressure. Lamination rollers are used for Paper laminators, Printed circuit board laminators, Dry film laminators, Cold lamination, Hot lamination. With four decades of industry experience in its quiver, Arvind Rub-Web Controls Ltd. has established itself as an industry leader in manufacturing, supplying, and export of a range of industrial rubber rollers!

Useful Guide To Discover About Pneumatic Air Chuck And Its Features

Pneumatic Air Chuck is also called a sliding jaw hurl. The Precision Air Chuck is incredibly easy to stack and unload and can be utilized by any operator. The jaw clip power can likewise be adapted to sensitive holding, and very advantageous for most meager divider workpieces. When appropriately mounted, all Air Chucks will naturally focus your workpiece. If you are searching for an exact hurl that can deal with various sorts and size parts, at that point the Precision Air Chuck is the correct decision for you. STANDARD FEATURES Summing Up So, it’s all about the Pneumatic Air Chuck and its features. In India, you can contact so many manufacturers and suppliers who give you specific air chunks as per your plant requirement. But before you choose any supplier keep this guide with you to get the best material as well as your needed air chunk. With four decades of industry experience in its quiver, Arvind Rub-Web Controls Ltd. has established itself as an industry leader in manufacturing, supplying, and export of a range of industrial rubber rollers and pneumatic air chuck among others!

What Is Bow Banana Roller, Its Types And Benefits? – Know In Depth

Bow Roll is known as spreader Roll, bowed Roll, Curve bar Expander, Banana Roll, Wrinkle Remover Roller, Bow rolls are accessible in hard chrome surface, elastic surface. Chrome surface bow Rolls are utilized where speed is in excess of 300 meters per minutes. Bow Banana Roller works when there is appropriate lead-in and lead-out distance and keep the move in legitimate twist point with web material. To do such twist point changing all rolls are provided with bow point changing worm-worm wheel gearbox with hand haggle platform bearing square, by utilization of this it is conceivable to change the bow point at 360 degree twist angle. When the Roll get most extreme wrinkle eliminating stop the bow point changing and put the move on bow bolted position, so not do any adjustment in the bow setting. On Roll shaft bow position sign with bolt indicating the bowed situation of the Roll. Banana Roller Expander having extremely wide scope of measurements and appropriate for similarly wide scope of uses and web materials. They are provided with mounting sections, which could be either divider mounting or foot mounting. The expander rollers by Manufacturer, India comprise of bowed shafts, fixed metal balls, scraped area safe sleeve and metal sections. These are generally utilized as wrinkle remover gadgets in different ventures and are accessible with us in different measurements. Types of Bow Roll accessible with us: Application of Bow Roller includes: The Performance of our Rubber Expander Roller (Bow Rollers) relies on: In this, 3:1 (lead-in: lead-out) proportion is viewed as the ideal. The best outcomes are achieved when Bow Roller is opposite to the web course. Advantages of our Bow Roller are: For 650 mm web width and web speed of under 50 meters/min a bow move of 90 mm is adequate with a shaft measurement of 30mm. For 4500 mm web width, 1000 mtrs / min speed requires least distance across of 160 mm roll and shaft breadth of 75mm or above. Bowed Roll is accessible in foot or spine mounting according to explicit prerequisites. The Bottom Line The Bow Banana Roller are utilized by the paper business at different degrees of creation like prior to calendaring, before pope reel, too when the size press. The techniques when Moreover, bow rollers for paper industry are additionally reasonable and encourages businesses to achieve seriousness. Other than assembling and supply rollers, we additionally fix and restore the pre-owned rollers to improve their productivity.

Industrial Rubber rollers are transforming the manufacturing sector

Before making a deep-dive into the all important industrial rubber rollers’ subject, it assumes significance to understand the fundamentals of the rubber roller. Understanding the rubber rollers A rubber roller in plain term can be defined as the sheet or coating of an elastic rubber covering the core made out of sturdy metal. Core metal depends on the application and industry. Ever rising market competition has compelled the manufacturing sector to employ premium quality rollers. In the long run quality pays dividend though bit expensive. Salient features of rubber rollers The industrial rubber rollers aren’t any kind of simple rubber rollers. These are identified with a variety of unique features: Uniform surface and precision driven cambering further elevates the salient features. Just a humble reminder – these salient features aren’t incorporated here for academic purpose. While making a purchase order, ensure that the rubber roller manufacturers finalized by you as a businessman demonstrates the above salient features. Mediocre quality wreaks havoc on the production cycle. As a businessman, it’s a precarious situation. And it’s totally avoidable. Application The rubber rollers are being employed in diverse manufacturing industries to perform various applications flawlessly, including: Industrial use The rubber roller has proved out to be a boon for different manufacturing processes. Owing to its efficiency, it’s being leveraged in several manufacturing industries, including textile, packaging, tyre, and paper among others. Custom rubber rollers The custom-designed rubber rollers are manufactured at a special order. Not many rubber roller manufacturers are equipped with the expertise and infrastructure to offer custom rubber roller, India solutions. Arvind Rub-Web Controls Ltd., a pioneer manufacturer, supplier, and exporter of industrial rubber roller with headquarter in Ahmedabad, India has been catering to diverse industries. An unmatched industry experience of four decades has been instrumental enabling the company to set industry benchmarks. Their unmatched position can be imagined from the fact that products are being exported to 50+ countries. Client trust hasn’t been built overnight; it’s the dedication, hard work and continued focus on quality that makes the company stand out from the crowd! The custom-designed rubber roller is one of their areas of expertise. Expert technicians and engineers collaborate with the client’s team. Understand their requirement. If you are searching for a industrial rubber roller manufacturer with proven track record, end your search with Arvind Rub-Web Controls Ltd. Summary The rubber rollers have become an integral part of a wide range of manufacturing industries. Depending on industry and application, businesses can choose and install the rubber roller. Never compromise with the quality. Quality directly impacts the business growth. Consequently, only procure rubber rollers from quality-driven companies!