Welcome to Arvind Rub-Web Controls Ltd - Your Trusted Industrial Rubber Roller Manufacturer in India

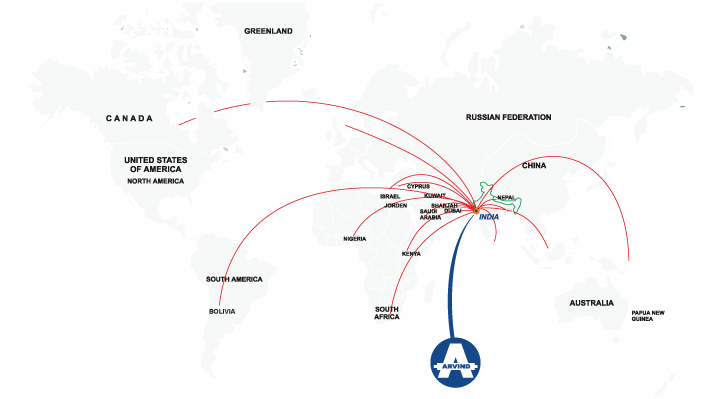

Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence focused company has established itself as an indisputable industry leader with several industry first to its credits. “Excellence means setting benchmarks, without telling others”, this adage has been at the center of our corporate strategy. Started with mere two industrial rollers in the beginning, over the years, we have thrived from the wealth of experience and now boast of 100+ product range and presence in 52+ countries!

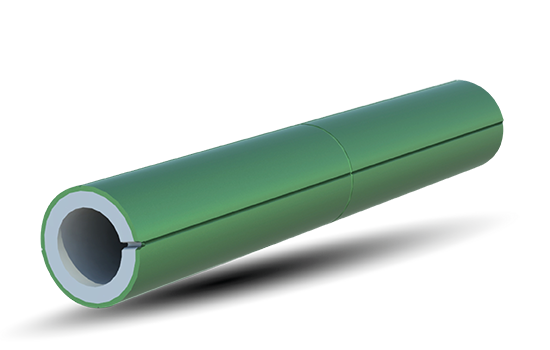

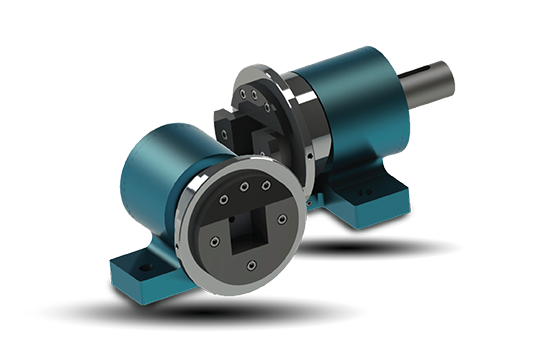

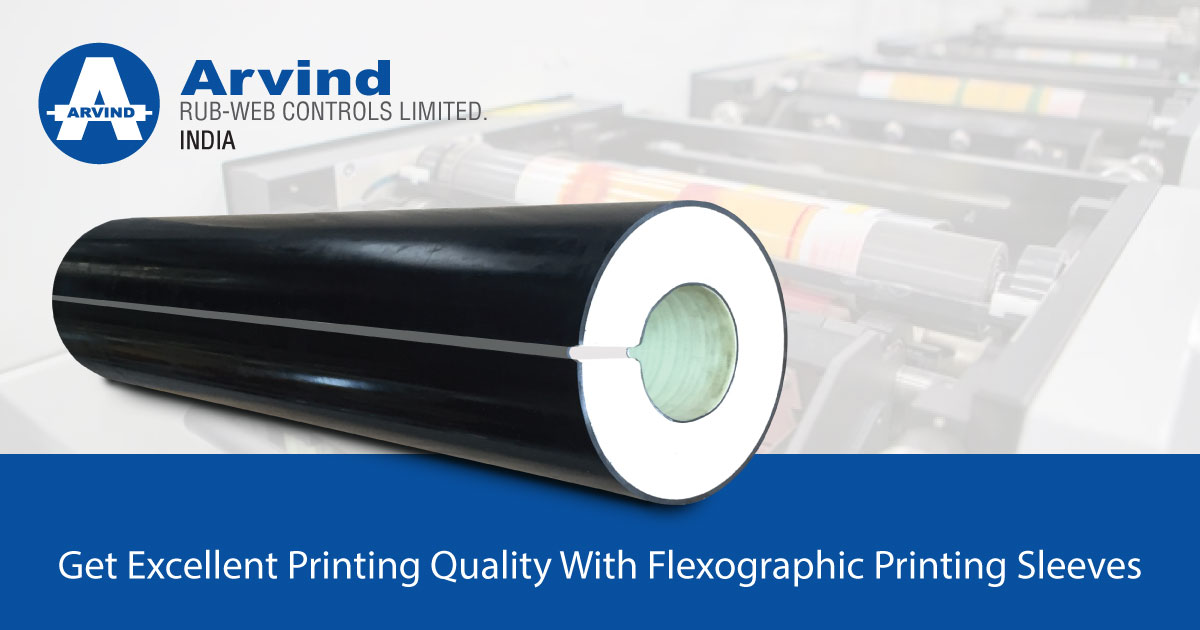

Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, air expandable shaft, and core saver/core restorer among others.

The industry-centric product range has been transforming business operations in plastic, printing, packaging, textile, paper, steel, tyre, and plywood industry among others!