Over the years roll grinding manufacturers have shifted towards innovative technology and machines, riding on multiple benefits offered by new-age technology. In this manufacturing industry-centric blog, we are going to focus on a wide range of important subjects related to roll grinding machine.

At the outset, it makes sense to define the industrial machine in simple language. It will help readers to relate to the blog in a better way.

Learning about the machine

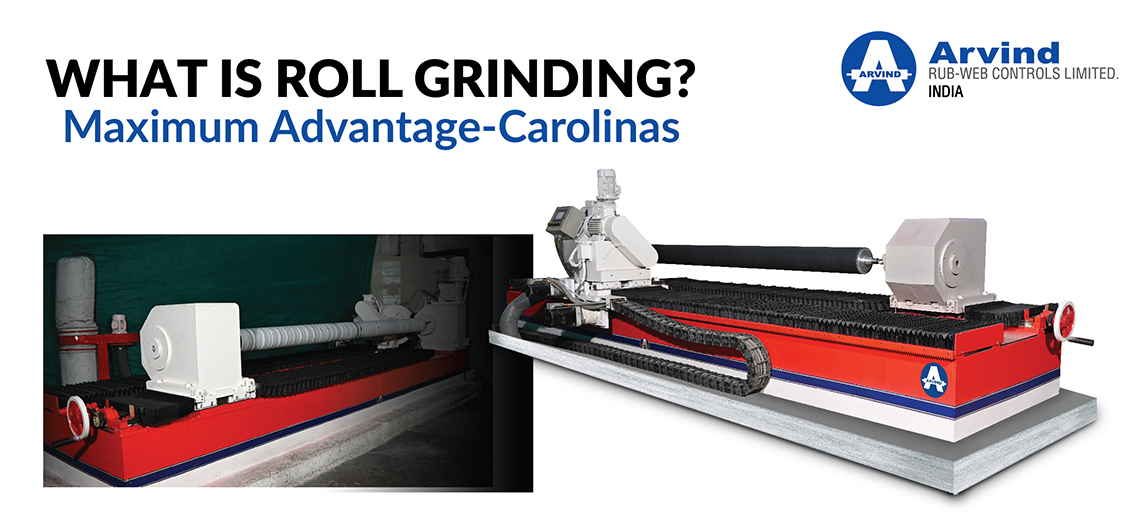

What is a roll grinding machine? It is a mechanized machine used for the purpose of grinding industrial rollers. The quality-driven machine is designed for material removal with geometrically non-defined, bonded cutting edges. As far as movement between tool and workpiece is concerned, it is rotational or linear. Each grain of abrasive present on the wheel’s surface cuts a small chip from the workpiece by deformation.

The machine has been fabricated to provide relative feed and positioning movements between tools and workpieces.

Talking about roll grinding machines, it is a typical method of processing wherein an abrasive wheel plays a key role. The robust wheel is used as a cutting tool. Besides roll grinding, the machine is also competent to carry out many milling tasks.

Salient features and properties

From the fundamentals, let’s now shift our focus to salient features and properties. In this era of ruthless market competition, Roll Grinding Machine Manufacturers are not leaving any stone unturned to deliver a quality-driven product. Therefore, salient features assume significance.

Different essential parts and their features

Main machine body

-

Specially designed body

-

Heavy, robust, and stable machine

Machine table

-

Spacious table with sturdy design

Wheel head

-

Engineered for high accuracy and long durability

-

Excellent surface finishing

Work head

-

Heat-treated, ground and lapped spindle runs on an antifriction bearing

-

Provides high accuracy & running to the spindle

Tail head

-

Designed and heat treated

-

Helps in achieving high accuracy

Hydraulic unit

-

The robust unit is housed outside the machine

-

Easy to clean and maintain

Electrical unit

-

Compact and centralized panel

-

Operator friendly

Lubrication

-

Inbuilt centralized lubrication system helps in managing the lubrication of the machine efficiently

Unique features

-

No skilled operator required

-

The precision achieved of 30 microns

-

Easy loading and unloading of rollers

-

Time-saving as its available in-house

-

Saves transportation time

-

Saves cost

-

Special attachment for Grinding wheel dressing

-

Easy to install and use

-

Dust collector for suction of rubber dust

-

User-friendly HMI Display

Application

In this section, we are going to talk about the application of the machine. The roll grinding machine is designed to perform a few special applications. These include:

-

Rubber roller Grinding

-

Chambering (crowning)

-

Step down processes

For further information, you can connect with a few Roll Grinding Machine Manufacturers of Ahmedabad, India. Finding a leading machine manufacturer isn’t a tough task in this era of technology. Go to the search engine. Enter a few keywords, like roll grinding machine manufacturers. The SERP will come up with a result. Click on the web pages. Browse the website comprehensively. Get in touch with their engineers and sales team.

Never compromise with the quality since your production line depends directly on the quality of the roller.

Industrial use

The manufacturing industry-centric machine is tailor-made for numerous industries, a few include:

-

Textile

-

Packaging

Customization

A few Roll Grinding Machine manufacturers hold expertise to deliver custom-made solutions. In case, you require a machine with specific dimensions, you can get in touch with a leader like Arvind Rub-Web Controls.

Conclusion

Quality speaks volume! It does wonders. Never buy redundant machine. Why take an useless risk.