In this business-centric blog, we are going to focus on a very important product, a grooved rubber roller. Over the years, this product has become an integral part of numerous manufacturing industries for its excellent applications.

Before we move forward and take a deep dive into the crucial subject, let’s learn about the roller.

Learning about the roller

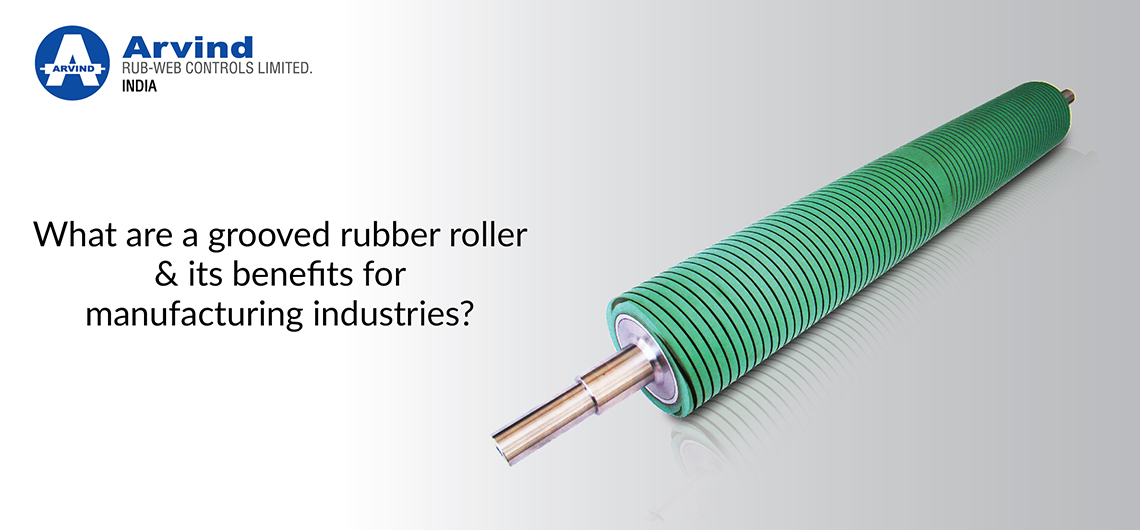

These are in fact industrial rubber rollers having distinctive groove patterns on the rubber surface. The groove pattern facilitates in developing cushioning and resonance. It is a distinctive feature that helps these rollers become competent to handle delicate films. In addition to this, this characteristic of the product helps in the process of wrinkle removal without causing any damage.

This is also famous as a rubber grooved spreader roller.

Design and dimensions

The grooved roller is available in various designs and dimensions. Based on your industrial requirement, you can choose the product. Spiral and straight grooved rollers are among the most sought-after designs in industry circles.

You can get in touch with leading rubber rolls manufacturers for your requirements.

Properties

Here are the properties of the product that show why our rubber grooved spreader rollers are the best:

-

Returns to its original shape, if distorted during application

-

Resistant to chemicals

-

High tensile strength

-

Resistant to wear and tear

-

Resistant to scratching and bumping

-

High coefficient of friction

-

Swiftly compensates to small changes that occur in machines precision

Salient feature

Here are the key features of the product that reflects our expertise and justify why our rubber grooved spreader rollers are the best:

-

Easy to install

-

Low maintenance

-

Durable

-

Dimensionally accurate

-

Sturdy material

-

Skilled labour not required to use

Applications

Here are the applications of the product:

-

Surface grinding of all dimeter & bearing

-

High-speed flexographic printing machine

-

Coating machines

-

Film plant

-

Spreading

-

Non-slipping

Industrial use

The business-centric product has been employed in numerous industries, including:

-

Packaging

-

Paper

How to choose the perfect product?

A product you are planning to buy for your manufacturing company shouldn’t be inferior. It should match industry standards, dimensional accuracy and matches your industry’s requirements.

Custom-made design

A few companies require specific designs and dimensions to meet their requirements. For such companies, custom-made design is suggested. Some leading companies like Arvind Rub-Web Controls Ltd. are professionally qualified to develop custom-made designs for your manufacturing company. Their expert and dexterous team with vast experience assesses and examines your requirements at the outset. Afterward, their expert engineers and technicians manufacture your kind of roller using a modern facility.

Summary

The quality of the roller makes all the difference. Therefore, never compromise with the quality. While choosing your product make sure it adheres to various quality standards.

In this era of technology, finding a brilliant manufacturer isn’t a big challenge. Use Google to explore manufacturers. Choose the best only!

Let’s join hands for a mutually beneficial partnership.

Driven by a visionary approach, Arvind Rub-Web Controls Ltd. made a humble beginning in 1984. From a modest foray, over the years, the excellence-focused company has established itself as an indisputable industry leader with several industries first to its credits.

Our quality-focused, industry-centric product range includes industrial rubber/ebonite/metal rollers, bow rollers (rubber/metal expanders), ink pumps, edge guider, bottom cutting shaft, rubber sleeve, hcp rollers, grooved rubber roller, air expandable shaft, rubber roller grinding machine, and core saver/core restorer among others.